As many here I have similar problems with my 2017 Twin EGR Ducato. I have the 177hp version. For me trouble started in 2021 roughly a year after buying the van, and got progressively worse. At that time the van had done around 175.000km. At first an error every morning and no more after clearing that. Later it got worse, limp mode every 50 - 100km or so, not funny. Before stumbling over this forum & thread I replaced the HP-EGR valve (no improvement), the turbo solenoid and the MAF sensor (again no improvement).

After reading about the DPF and LP-EGR circuit causing this trouble and analysing with

MES early 2022 I had ECU prog v32 installed and had a new DPF installed (ouch), also had the LP-EGR cooler and the LP-EGR valve changed out by a clean used pair I bought used. This solved the problem, it was at around 180.000km.

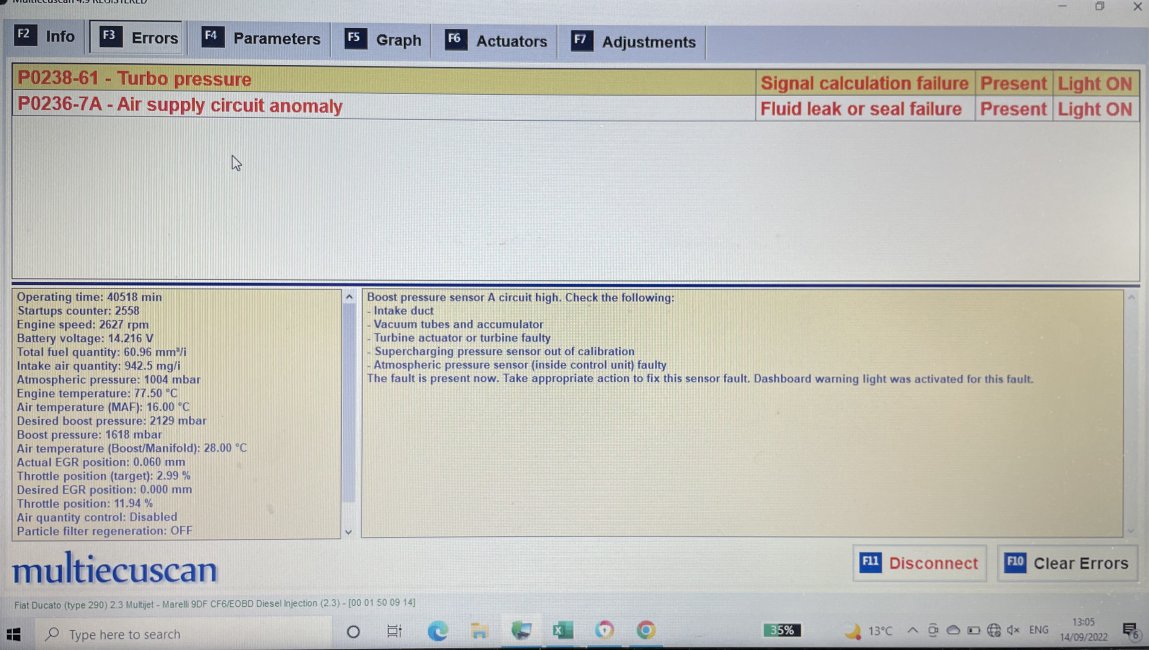

But now, some 40.000km further, the P238, P401 and limp mode are occurring again... I have done a longer testrun with

MES logging using dataset #5. After ca 5 min the P0238 and P0401 errors occured. After clearing these, in the following drive no more errors. See attached freeze frame snapshots and the log files before the error, and the longer / warm engine drive after that.

My analysis is the LP-EGR is (getting) obstructed again, an independent check is welcome...

- Temperature after LP-EGR cooler is max 100degC, average 60-65degC.

- LP-EGR valve is mainly travelling between 0 and 4.7 (but is also showing mid range values).

- The DPF dP ranges from 10-65mbar which is not bad - but doesn't say much about there being a 'crack' in the DPF or not.

- Finally I've seen that the injector correction values range up to and above 3mm3/i - outside the FIAT recommended maximum of 2mm3/i (should I consider to have them replaced?).

I have a service scheduled for November 6th, and informed the dealer I will most likely want to have my 'spare' cleaned LP-EGR cooler installed. Also I've indicated that the DPF is supposed to have 24 months guarantee (will see what the dealer says about that).

Since I also have a spare LP-EGR valve, I have the option to make and test the mod that

@Fredastaire proposed earlier - to change the 'disc cam' that operates the valve in the clean air inlet such that it does not fully close / stays open.

One question I have for that is concerning the checks the ECU can (and will) do. I would expect the ECU to check that the airflow sensor reads (close to) zero when the LP-EGR valve is fully closed. That can be done by the ECU - if the air flow sensor is upstream the LP-EGR valve. My van is not at home for another week (daugther is in Spain with it). Can someone check / confirm if there is an air flow sensor upstream the valve? If so I am not sure I want to try the 'disc cam' mod as it is likely to cause other limp mode failure codes.

I am -very- interested though in the result of the HP- and LP-EGR removal ECU tune that

@Poachersmoon has done. If that proves to work without errors, getting the tuning company to make a version that only disables the LP-EGR would be my choice.