@BoultsG have a read of this guide. if you run my template 5 save the results as a csv fill and post them here. I will look at the results and advise as appropriate.

the paper towel wipe the exhaust test is also vital to understanding whats going on.

This was originally written to help one person with his Ducato totally new to

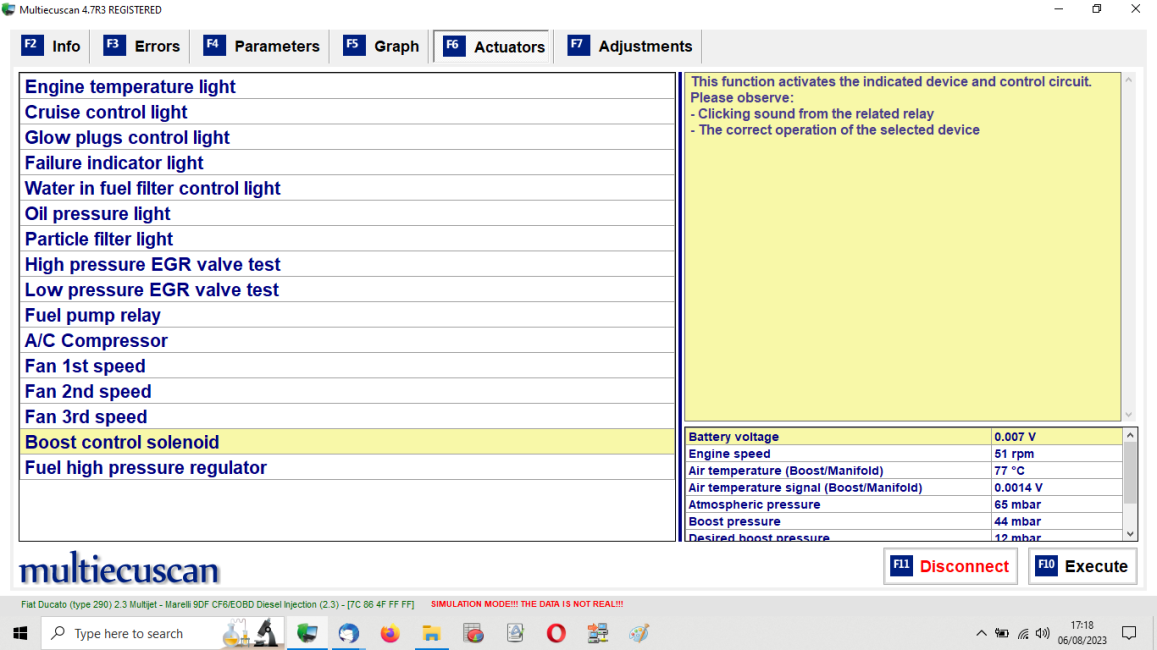

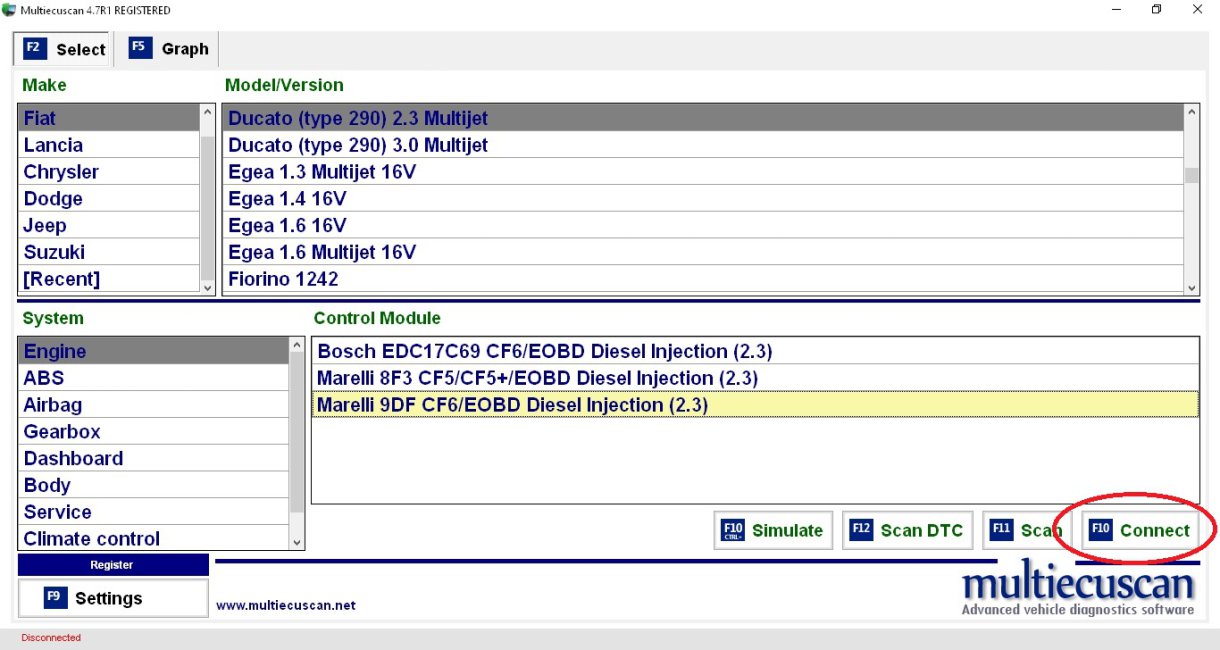

MES to start saving data. it is not an exhaustive manual nor intended to be. Tutorial to Measure specific Engine PIDs (Parameter ID) and Save data for analysis. Open...

www.fiatforum.com

Do you when the ecu was last updated and how many updates (page2 info). now is not the time to jump to conclusions and paranoia. lets do this one step at a time. Several people have had serious problems and have been repaired. There is only one i know of that has had a repeated problem but that was due to diesel bug.

If you get

mes sorted and can run template 5 for a few days and issolate precisely when a 401 occurs it will help. if you can do a screen shot of the freeze frame that can help. (freeze frame is the screen shown when the error is highlighted (f3). If you can constantly run

mes then as a mil occurs you can delete it. This will get you home. Record as much info as possible. From engine data i have from 15 engines the 401 occur in a simular way. We need to see data to understand what is happening and evaluate how blocked your dpf is.

Please confirm engine details eg 2.3 130, 150 year 2017-1019 no adblu

Are you still travelling or at home?