You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

General Ducato 3.0 multijet 160 comformatic fix selespeed magnetti

- Thread starter Seanwinder22

- Start date

Currently reading:

General Ducato 3.0 multijet 160 comformatic fix selespeed magnetti

Seanwinder22

Member

Thanks yes mine is also 348These are mine that I've just taken. My parameters are different to yours. Mine is an 348... my clutch disk speed is zero...

Thanks for the images

Since testing this afternoon and getting it up to temp the rpm has not been back it’s stayed on 0 so

Maybe the slave is leaking or clutch bearing

We shall see

growlybear

Member

Great news!Thanks yes mine is also 348

Thanks for the images

Since testing this afternoon and getting it up to temp the rpm has not been back it’s stayed on 0 soall can do now is enjoy it

Maybe the slave is leaking or clutch bearing

We shall see

- Joined

- Sep 25, 2011

- Messages

- 157

- Points

- 86

The Comfortmatic is designed to keep the clutch depressed also in Neutral at standstill with engine running, i.e clutch speed 0 rpm is the normal in this situation. This is also used as a verification step in the clutch bleed procedure described in eLearn, if the speed is not 0 it may be a sign of air in the clutch circuit:Thanks yes mine is also 348

Thanks for the images

Since testing this afternoon and getting it up to temp the rpm has not been back it’s stayed on 0 soall can do now is enjoy it

Maybe the slave is leaking or clutch bearing

We shall see

(Shortly after starting the engine the clutch speed may briefly be higher than 0 rpm while the robot is doing the Kiss Point check.)

Last edited:

growlybear

Member

I read this too on another thread. Surprised me as in neutral with a conventional released clutch, the engine and clutch speeds would be identical.The Comfortmatic is designed to keep the clutch depressed also in Neutral at standstill with engine running, i.e clutch speed 0 rpm is the normal in this situation.

Clearwater

New member

Hi Sean - trolling the internet for items to check on my Hymer A Class B674SL 2009 3.0 Comformatic Box.I wanted to post my feedback and finding on my issue I faced and fixed with my comfortmatic gear box but wanted to say this worked for me I’m not saying it’s everyone’s issue yours could be a different contact or sensor but still my findings point to the harness or contacts

I had the No transmission fault no gears available check handbook …. So I’ve owned a comfortmatic years and knew about these issues from a friend and others that have faced similar issues

Many talks with Fiat and commercial truckers garages and iveco or promaster threads etc I really dived into these issues on many cases and was told this that 98% of issues relating no transmission was the harness or contacts or electric fault

Very few cases gear box removed or clutch and still may have not been that but was changed anyway

In hopes

I first got this so know first hand garages do say new gear box / clutch and try the expensive changes first it seems working through parts ticking off a list …. Not all but most garage. I was lucky in away having helped a friend have sensor issues regarding this m40 gear box so it’s the first I tried

What I did while vehicle was running well the AA guy did after I told him

Was he moved the selespeed harness while engine running which we heard a clink no more beeping no transmission on dash

Moved it again it came back in the dash

On the rear of the gear box easy through battery tray when battery removed to get to unplug the 4 in question, you will see on this harness evo 0.1.2.3 mine was the contact on the gear engagement it was broken and a short was happening so I removed the harness completely stripped the plug and purchased the new one from te connectivity job complete

A year later it happens again slowly approaching a roundaboutparked up got under unplugged and cleaned with contact cleaner all good

Got me home this time was the actual sensor

My point is the leaks these Ducatos have especially if a old ish van 2006 to 2010 scuttle leaks etc dropping on the gear box corroding sensors and contacts issue after issue

Only using the van a few months out the year is very bad for this also

Get the scuttle tray sorted first

Get the harness taped up nice and clamp down to stop movement this also weekens contacts or brakes

Get wiring around headlight

Earth strap

My 3.0 also the starter battery was only 95ah I changed to 110ah big difference

Cleaned all contacts on plugs then filled them with electrical snot forgot the name to stop any issues getting in

I bled the small reservoir very old fluid filled with patronas dot 4

Changed hydraulic fluid rectangle reservoir filled with new patronas cs speed 75w

Dropped gear box oil 2.9 filled with new patronas transmission geartech 75w-85

Cleaned brake switch

It’s now running brilliantly had no issues at all

But to keep on top of this I will clean the harness contacts every year because they was badly corroded first one was damaged

I may even look into the relearn after changing the clutch speed sensor I didn’t do anything with the smart/plus or multiscan just disconnected the battery before any work carried out

Just reading up now on the gearbox update and relearn procedure

Anything to try get this sorted for good

But I’ve not owned the van from new so you don’t know how long leaks have gone on for etc so corrosion had already started on the harness contacts

So I suspect on the gear box side of sensors or female plugs would have been the same so clean bothit’s a time consuming job so glad I did this myself

You appear to know quite a bit so hope you don’t mind me reaching out for some knowledge

Van has stood for 3 months, go to start, get the warning beep, flashing red gerbox symbol, stuck in 1st, won’t start and message ‘gear not available check handbook’

I’ve been through all fuses, battery is good, have disconnected battery for 20 minutes hydraulic pump seems to be running, engine bay is dry around wiring - waiting to get MES for codes

Was wondering if you had any other pointers - there has been 2 occasions in the past 12 months where ‘gear selection not available’ but cleared with turning off and on again

Great if you could share some areas to check a bit more detail

Thanks

Seanwinder22

Member

Hi mateHi Sean - trolling the internet for items to check on my Hymer A Class B674SL 2009 3.0 Comformatic Box.

You appear to know quite a bit so hope you don’t mind me reaching out for some knowledge

Van has stood for 3 months, go to start, get the warning beep, flashing red gerbox symbol, stuck in 1st, won’t start and message ‘gear not available check handbook’

I’ve been through all fuses, battery is good, have disconnected battery for 20 minutes hydraulic pump seems to be running, engine bay is dry around wiring - waiting to get MES for codes

Was wondering if you had any other pointers - there has been 2 occasions in the past 12 months where ‘gear selection not available’ but cleared with turning off and on again

Great if you could share some areas to check a bit more detail

Thanks

All I can see is read the start of this thread watch all videos of mine on the channel I set up to show issues with the selespeed

First you need the fault codes without them we are really blind mate

All you can do while you wait is tests

I suggest unplugging the selespeed harness and cleaning contacts especially the gear sensor which is the long black one behind the airbox then below this is the clutch position sensor get some contact spray and give a good clean by plugging and unplugging a few times will get contacts nice and clean mate

Check the clutch fluid reservoir 6mm from the top

And the large transmission reservoir half way but to check this one do it on a morning don’t open drivers door at all or put key in ignition it activate the pump

What I do to check level I take negative from battery half a day then check levels

Next up under the van the front of battery tray you will see the selespeed robot you will see the black accumulator then to the left of it 4 plugs labelled Evo0 Evo1 Evi2 Evo3 un

Plug these and clean mate and look making sure no pins are bent or broke.

I actually took off the complete selespeed harness and checks. Cleaned all contacts check continuity of it with multimeter

You say all fuses are fine and what about relays ?

With the comfortmatic in the engine bay we have extra fuses f24 f26 f27

But like I mentioned you have to check very close any wires and plugs even on engine like egr and any sensor make sure no splits

MAIN ONE. Is gear box to chassis strap it always looks fine but they corrode inside

I take it off and sand down the metal body then buy new strap or make one

A temp one is a jump lead to test

But I have 2 straps now in my engine and main one from battery to chassis this helped

I also charged my starter battery because even now if I leave van to sit few weeks I get issues showing triangle on dash this then causes transmission issues

To get around this I bought a trickle charger from wildebus called

Ablemail AMT-12 Battery Maintainer

Also check the brake switch but honestly read this thread

Attachments

Seanwinder22

Member

Also tell me a little history of the van pleaseHi Sean - trolling the internet for items to check on my Hymer A Class B674SL 2009 3.0 Comformatic Box.

You appear to know quite a bit so hope you don’t mind me reaching out for some knowledge

Van has stood for 3 months, go to start, get the warning beep, flashing red gerbox symbol, stuck in 1st, won’t start and message ‘gear not available check handbook’

I’ve been through all fuses, battery is good, have disconnected battery for 20 minutes hydraulic pump seems to be running, engine bay is dry around wiring - waiting to get MES for codes

Was wondering if you had any other pointers - there has been 2 occasions in the past 12 months where ‘gear selection not available’ but cleared with turning off and on again

Great if you could share some areas to check a bit more detail

Thanks

How long you owned it ? Has this happened before?

Can you remember the last time the selespeed got a good service ?

You mentioned stood 3 months ? which in return isn’t good mate especially no start ups

Thing is with this engine and scuttle the bloody leaks they are terrible

I know first hand because did the timing chain on my 3.0 litre so got to see the state of the rear of the engine it was terrible full of rust

God help me if I ever have a injection issue

Reason I set out to change my front end to facelift and stop all leaks

What I do now every month I spray on my injectors and engine ACF50 which keeps things coated and waterproof

Anyway back to you …. get leaks sorted first job

How do we test if got a leak ? Easy cut some Amazon box down and place on engine all at the back and use hose pipe spray window a good rinse then look inside on area which will be water marked on the card

Get some sealant and fix scuttle to window

Check all hoses are not blocked

Buy the mod for the airbox leak I have a video showing how to fit this

Just remember a van sat 12 week in rain and cold and with leaks will give you issues

So what I recommend is unplugging all selespeed contacts and cleaning even use a hairdryer to dry them inside mate

Remove passenger headlight and check rusty junction the main harness under it and I mean remove tape and slevving and inspect

This harness goes from under headlight to the fuel filter and then under the scuttle tray all along to bulkhead and then goes in a grommet inside the bulkhead down to the brake peddle area

On the bulkhead the harness can rub and short out

What I did after inspecting wiring I then placed some armour over it and taped up for future will protect it no matter what

Then check brake switch on the brake pedal it’s above the peddle so put your hand upwards and feel for a sensor and wires

The switch you turn to the right and it pulls out

Then unclip from wires and clean

But a quick test is turn lights on and check if brake light is on

This effects the transmission because thinks you are braking so won’t go into gear

You press throttle and brake same time it gives you the no gears available

So can also clean all rear bulbs up and contacts this is another can issue I have had even bulbs not sat right

A garage for my mot helped out changing bulbs but fitted the wrong ones this caused issue with transmission

The transmission is very delicate and any short or spike it sets up faults

But to me going off what you say it’s been parked up and since trying you get this warning is just minor shorting from water damage or damp again from water

Each time you try something write down and post up here you will sort it mate

Seanwinder22

Member

Going back to this post after talking to a guy that services this robot and only this robot he tells me you carry out a few adjustments after clutch fluid changes and transmission and sensors and harness being removed needs relearning even the relay so parameters need to be reset and relearnedIn mes known has multiecuscan carry out in this order and do what it says what I post on images View attachment 455816

actuator base adjustor with production/ service final calibration which is needed after changing the sensor for engagement or selection which is settings for degradation index which after years can miss calculated so resets it degradation which would happen when fitting new clutch so it will adjust in setting even if a new clutch hasn’t been fitted

The clutch degradation index calculation procedure is required by the MTA control unit because itstores characteristic values for each specific clutch in its Eeprom, taking into account normal clutch wear over time.

Obviously it can not fix a warn plate just the settings that have been missed and catch’s up I may be explaining it rubbish but it basically does a reset of gearbox and clutch kiss point

Normally after a clutch out but if you replace the clutch position sensor don’t get confused with speed sensors the clutch sensor is a potentiametres so has new parameters so old parameters need to be reset and new learnt

So carry out like this if has I mentioned replacing the relay for pump

Bleeding clutch fluid and new

New transmission oil

Removing selespeed harness changing potentiometer sensors ie clutch position or gear sensor so take screenshots of old parameters all settings of gear engagement position and clutch engaged position self adjusted so in this order

delete statistical data

Electro pump replacement

Clutch replacement

Actuator base adjustment

Clutch drain x3

Then carry out production service final calibration

Then compare parameters from old to new looking at new values

Check your degradation index

- Joined

- Sep 25, 2011

- Messages

- 157

- Points

- 86

.... hydraulic pump seems to be running....

When do you notice that the pump is running and for how long does it run?

Clearwater

New member

Hi - thanks for your help - as it’s a A-Class there is more room in engine bay - windscreen doesn’t have the drainage scuttles, nor does harness go near wipers.Also tell me a little history of the van please

How long you owned it ? Has this happened before?

Can you remember the last time the selespeed got a good service ?

You mentioned stood 3 months ? which in return isn’t good mate especially no start ups

Thing is with this engine and scuttle the bloody leaks they are terrible

I know first hand because did the timing chain on my 3.0 litre so got to see the state of the rear of the engine it was terrible full of rust

God help me if I ever have a injection issue

Reason I set out to change my front end to facelift and stop all leaks

What I do now every month I spray on my injectors and engine ACF50 which keeps things coated and waterproof

Anyway back to you …. get leaks sorted first job

How do we test if got a leak ? Easy cut some Amazon box down and place on engine all at the back and use hose pipe spray window a good rinse then look inside on area which will be water marked on the card

Get some sealant and fix scuttle to window

Check all hoses are not blocked

Buy the mod for the airbox leak I have a video showing how to fit this

Just remember a van sat 12 week in rain and cold and with leaks will give you issues

So what I recommend is unplugging all selespeed contacts and cleaning even use a hairdryer to dry them inside mate

Remove passenger headlight and check rusty junction the main harness under it and I mean remove tape and slevving and inspect

This harness goes from under headlight to the fuel filter and then under the scuttle tray all along to bulkhead and then goes in a grommet inside the bulkhead down to the brake peddle area

On the bulkhead the harness can rub and short out

What I did after inspecting wiring I then placed some armour over it and taped up for future will protect it no matter what

Then check brake switch on the brake pedal it’s above the peddle so put your hand upwards and feel for a sensor and wires

The switch you turn to the right and it pulls out

Then unclip from wires and clean

But a quick test is turn lights on and check if brake light is on

This effects the transmission because thinks you are braking so won’t go into gear

You press throttle and brake same time it gives you the no gears available

So can also clean all rear bulbs up and contacts this is another can issue I have had even bulbs not sat right

A garage for my mot helped out changing bulbs but fitted the wrong ones this caused issue with transmission

The transmission is very delicate and any short or spike it sets up faults

But to me going off what you say it’s been parked up and since trying you get this warning is just minor shorting from water damage or damp again from water

Each time you try something write down and post up here you will sort it mate

It’s exceptionally clean and dry but they do leave a lot of wiring hanging behind headlight units and to drls (which I have changed in June to leds to avoid headlamp heat failure - I might check all them areas)

Brake lights work on switch

If brake pedal and throttle pressed down together makes no difference

Had the van 3 years - very low mileage 22k - do not think gearbox has been serviced - something that will need doing - I’ve had the problem possibly 3 times this year - once when driving it said no gear but fiddling into manual and back got auto again - once more early September on start up - no gears wouldn’t start, switched ignition off and on and cleared - then this time but nothing

I’m sure it’s electrical as you say - had same with canbus on a machine I use for work - ended up checking all connections and last one had a little bit of white dust - was all sorted after that and a lot of costs for people looking at it

Clearwater

New member

As mine is AClass I don’t think pump is switched on until key is turned to on pos.When do you notice that the pump is running and for how long does it run?

There is a whirring sound from beneath battery box, which runs for 17 seconds

- Joined

- Sep 25, 2011

- Messages

- 157

- Points

- 86

That sounds a bit long to me. Mine runs for 4 seconds and I have seen similar numbers reported from several others. However, to my knowledge there is no official statement of what the "right" run time is. If/when the pressure accumulator loses its capacity it will initially lead to longer pump times, more frequent pump starts and perhaps poor functionality. But as already said, without checking for error codes and parameter values with MES or similar, its harder to locate what's wrong.As mine is AClass I don’t think pump is switched on until key is turned to on pos.

There is a whirring sound from beneath battery box, which runs for 17 seconds

Seanwinder22

Member

I would wait for the multiecuscan to arriveHi - thanks for your help - as it’s a A-Class there is more room in engine bay - windscreen doesn’t have the drainage scuttles, nor does harness go near wipers.

It’s exceptionally clean and dry but they do leave a lot of wiring hanging behind headlight units and to drls (which I have changed in June to leds to avoid headlamp heat failure - I might check all them areas)

Brake lights work on switch

If brake pedal and throttle pressed down together makes no difference

Had the van 3 years - very low mileage 22k - do not think gearbox has been serviced - something that will need doing - I’ve had the problem possibly 3 times this year - once when driving it said no gear but fiddling into manual and back got auto again - once more early September on start up - no gears wouldn’t start, switched ignition off and on and cleared - then this time but nothing

I’m sure it’s electrical as you say - had same with canbus on a machine I use for work - ended up checking all connections and last one had a little bit of white dust - was all sorted after that and a lot of costs for people looking at it

Its honestly going in blind at the moment

You need codes mate

Seanwinder22

Member

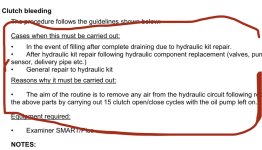

Ok guys I want to talk about clutch drain in mes

Has anyone in the thread done this ?

Because I was told you just execute the command and mes does the work

Which concerns me a little because here’s what I’m reading

The aim of the routine is to remove any air from the hydraulic circuit following replacement of etc

the above parts by carrying out 15 clutch open/close cycles with the oil pump left on.

So it says above open/close cycles

So does this mean with equipment set up you use to bleed clutch a hose connected to the bleed valve which you have to open / close to let clutch fluid out or air

So I’m assuming I was given the wrong information here saying just execute the clutch drain and it bleeds the air from the system and air will flow to the reservoir

I don’t think you do that at all

Open close cycles will be opening the bleed valve then pressing execute in mes which will pump the clutch fluid and any air in the system

I feel if you carry out the execute command without opening the bleed valve this will cause problems

Has anyone in the thread done this ?

Because I was told you just execute the command and mes does the work

Which concerns me a little because here’s what I’m reading

The aim of the routine is to remove any air from the hydraulic circuit following replacement of etc

the above parts by carrying out 15 clutch open/close cycles with the oil pump left on.

So it says above open/close cycles

So does this mean with equipment set up you use to bleed clutch a hose connected to the bleed valve which you have to open / close to let clutch fluid out or air

So I’m assuming I was given the wrong information here saying just execute the clutch drain and it bleeds the air from the system and air will flow to the reservoir

I don’t think you do that at all

Open close cycles will be opening the bleed valve then pressing execute in mes which will pump the clutch fluid and any air in the system

I feel if you carry out the execute command without opening the bleed valve this will cause problems

growlybear

Member

I don't see how you are meant to open and close the bleed nipple when you don't know when to open or close. It's also done with the brake pedal pressed so you'll need someone else toodoes this mean with equipment set up you use to bleed clutch a hose connected to the bleed valve which you have to open / close to let clutch fluid out or air

Seanwinder22

Member

I think it’s confusing in mes because it’s actually talking about the transmission which is large reservoir and bleeding that systemI don't see how you are meant to open and close the bleed nipple when you don't know when to open or close. It's also done with the brake pedal pressed so you'll need someone else too

The dot 4 system there is nothing in mes

And what you say about the brake peddle yes correct but I think that’s a one reservoir manual that share clutch / brake reservoir

Don’t forget with this system clutch and brake pedal is one I don’t think you touch the brake pedal only when bleeding brakes

Seanwinder22

Member

I have only had multiecuscan one month so still learning

When I changed my clutch fluid I did it manually

I sucked out clutch fluid small reservoir while then I open bleed valve and push new dot 4 fluid threw to fill small reservoir back up and repeat

I actually think it’s the hydraulic cs speed air bleeding that multiecuscan does it bleeds this system I may be wrong but I think I’m right about that tbh

I do however think I have some trapped air I need to bleed out the system the reason I seen clutch rpm has someone posted yesterday trapped air will raise clutch rpm

But no mention of how to get trapped air from a comfortmatic is available, on a pure manual that has separate clutch and brake pedal you press clutch pedal

But this being the brake/clutch pedal maybe I should bleed the whole system brake lines which will bleed clutch with it being shared

When I changed my clutch fluid I did it manually

I sucked out clutch fluid small reservoir while then I open bleed valve and push new dot 4 fluid threw to fill small reservoir back up and repeat

I actually think it’s the hydraulic cs speed air bleeding that multiecuscan does it bleeds this system I may be wrong but I think I’m right about that tbh

I do however think I have some trapped air I need to bleed out the system the reason I seen clutch rpm has someone posted yesterday trapped air will raise clutch rpm

But no mention of how to get trapped air from a comfortmatic is available, on a pure manual that has separate clutch and brake pedal you press clutch pedal

But this being the brake/clutch pedal maybe I should bleed the whole system brake lines which will bleed clutch with it being shared

Seanwinder22

Member

Yep has I thought multiecuscan is only for bleeding the hydraulic system for cs speed once changing anything on hydraulic side

Has in transmission

It is not talking about the dot 4 clutch side or small reservoir

So if you get air in the system when changing dot 4 that’s got to be the same process when bleeding brakes like you mentioned buddy surely

Has in transmission

It is not talking about the dot 4 clutch side or small reservoir

So if you get air in the system when changing dot 4 that’s got to be the same process when bleeding brakes like you mentioned buddy surely

Attachments

Seanwinder22

Member

Sorry if I confused you because I confused myself not explaining greatI don't see how you are meant to open and close the bleed nipple when you don't know when to open or close. It's also done with the brake pedal pressed so you'll need someone else too

The cs speed when changing this is when you carry out clutch drain in mes for trapped air

I think I got air in the system when changing dot 4 and bled the system

The bleed valve is for dot 4

The transmission large reservoir doesn’t have a bleed valve for the clutch

See how it’s confusing to talk about

So yes I bleed the dot 4 so when someone posted yesterday about the clutch rpm I was under the impression trapped air from the clutch bleeding with dot 4

But now I think they are meaning trapped air in the actual transmission reservoir tank when filling with cs speed

Similar threads

- Replies

- 14

- Views

- 396