aschoots

Member

Picked up the van today after a long stay at the dealer (beginning of November). Logged set #5 with MES to see how it performs now, file attached.

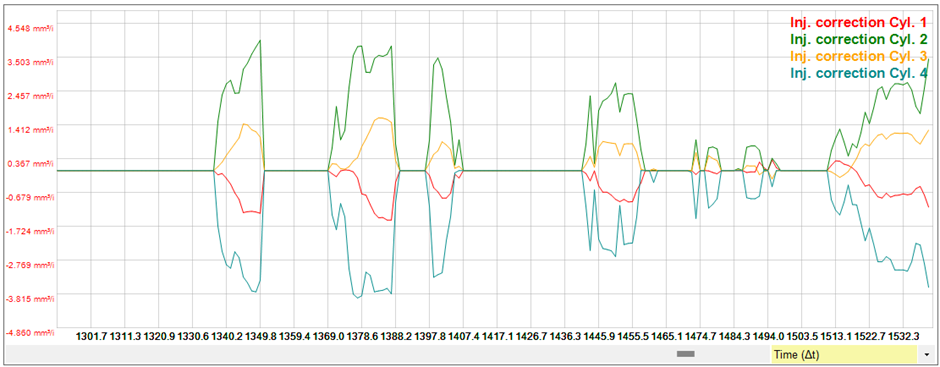

Reason for the long stay: Engine service (fresh oil and filter, brake fluid, etc), had the cracked DPF (very high soot particle count) fitted with new internals by local company (soot count now perfect), had ordered a Krosfou DPF at first but that did not fit correctly (still waiting for an RMA number & refund), fitted a clean -used- LP-EGR cooler (was completely blocked), fitted a revised Turbo (it had oil leakage into air side), had the injectors tested as MES showed up to +/- 3.5mm3/s correction.

Injectors – well over FIAT limit of +/- 2mm3/s. Strange, as injectors have been tested and are reported as OK…

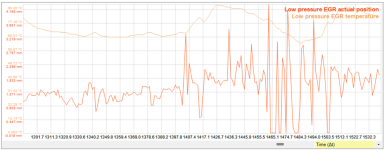

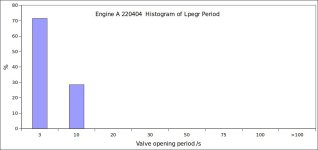

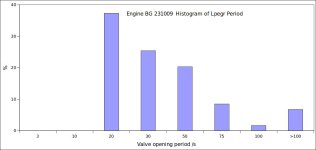

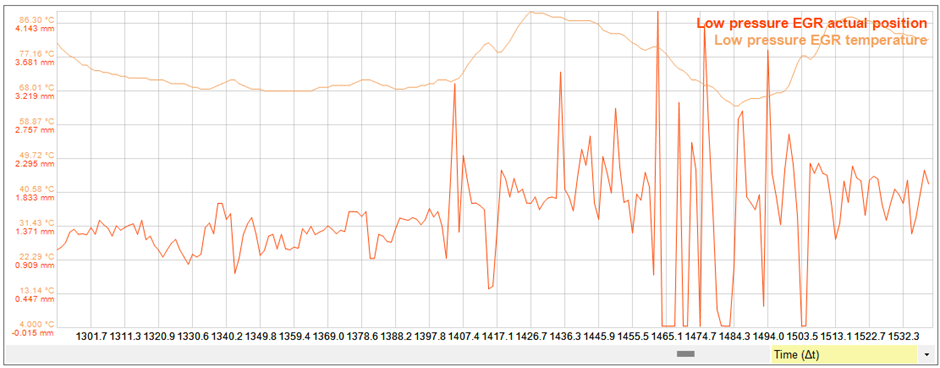

LP-EGR system now works as intended / no more blocked LP-EGR cooler.

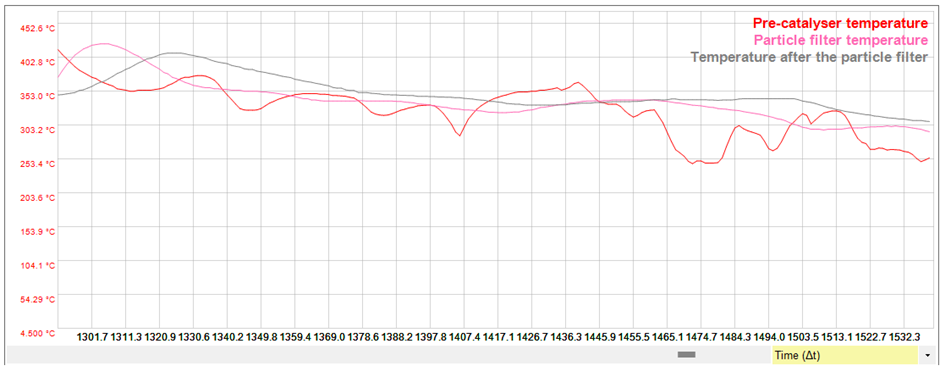

Temperatures around DPF / cat are OK.

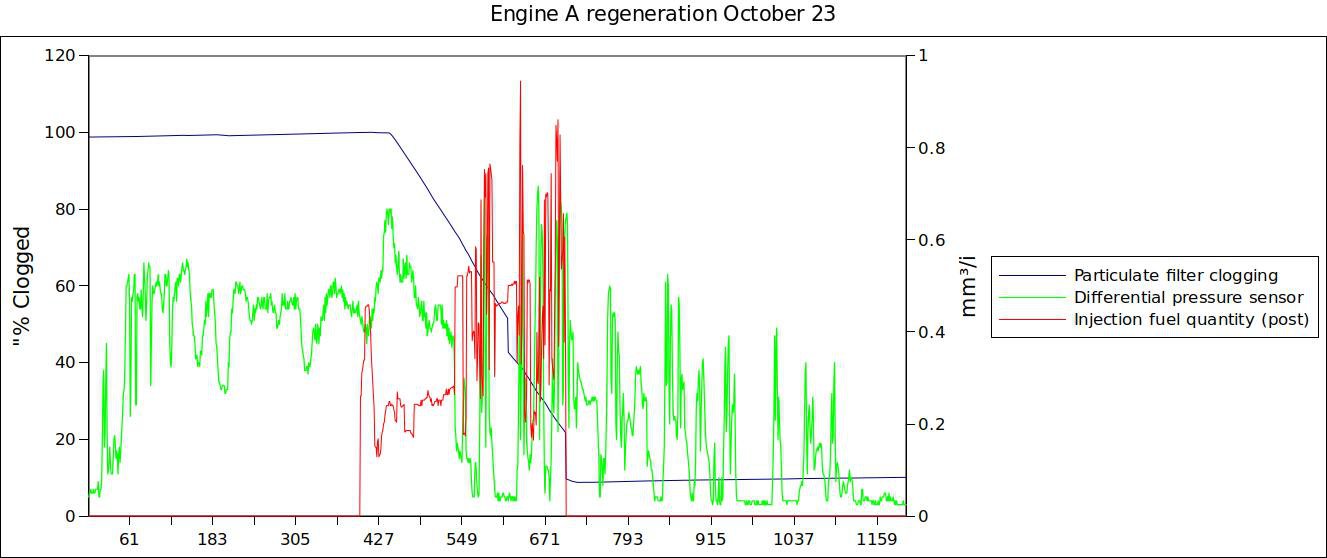

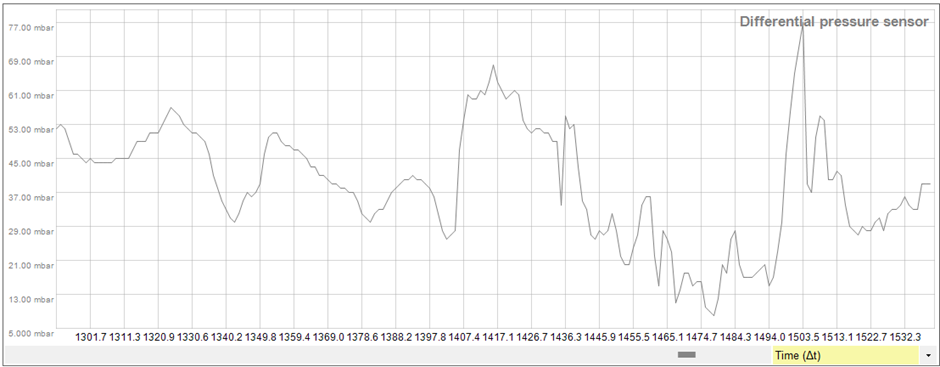

DPF differential pressure looks OK.

Next planned step is to implement an ECU map mod that stops LP-EGR from working, so no more exhaust gas with a small (or bigger) amount of soot particles travelling back to the ‘clean’ inlet side of the engine. And -if it all works out- no more P401/402/238 limp mode errors.

This mod was done by @Poachersmoon (NZ), I’ve contacted Peter James Tuning (NZ), and worked with my local tuner Squadra (NL) to get prepared. Next steps are as follows:

Note: The Powergate holds the original downloaded file as well as one or more modded files, which enables the options to go back to original before MOT testing and to mod after.

Note: There is also a LP+HP EGR mod (disabling them both) available. I want to stay at least a bit compliant, so not doing that one.

I will post an update when there is something to report.

Reason for the long stay: Engine service (fresh oil and filter, brake fluid, etc), had the cracked DPF (very high soot particle count) fitted with new internals by local company (soot count now perfect), had ordered a Krosfou DPF at first but that did not fit correctly (still waiting for an RMA number & refund), fitted a clean -used- LP-EGR cooler (was completely blocked), fitted a revised Turbo (it had oil leakage into air side), had the injectors tested as MES showed up to +/- 3.5mm3/s correction.

Injectors – well over FIAT limit of +/- 2mm3/s. Strange, as injectors have been tested and are reported as OK…

LP-EGR system now works as intended / no more blocked LP-EGR cooler.

Temperatures around DPF / cat are OK.

DPF differential pressure looks OK.

Next planned step is to implement an ECU map mod that stops LP-EGR from working, so no more exhaust gas with a small (or bigger) amount of soot particles travelling back to the ‘clean’ inlet side of the engine. And -if it all works out- no more P401/402/238 limp mode errors.

This mod was done by @Poachersmoon (NZ), I’ve contacted Peter James Tuning (NZ), and worked with my local tuner Squadra (NL) to get prepared. Next steps are as follows:

- Read current ECU file (v32 with Squadra mod) using the Powergate 3+ tool.

- Download from Powergate to PC

- Send the file to Squadra (or Peter James Tuning if you live in NZ/AUS) for applying the LP-EGR modification

- Upload file from PC to Powergate

- Load from Powergate to ECU

Note: The Powergate holds the original downloaded file as well as one or more modded files, which enables the options to go back to original before MOT testing and to mod after.

Note: There is also a LP+HP EGR mod (disabling them both) available. I want to stay at least a bit compliant, so not doing that one.

I will post an update when there is something to report.