Hi

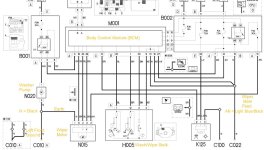

This is proving to be a bit of a head scratcher, but the fact that main beam is OK gives a clue. The X250 has two Fuse/Relay/Connection modules, one in the engine bay and one under the dashboard.

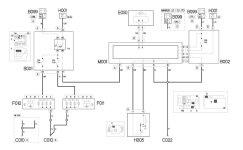

The Engine Bay Fuses B001 are mostly for things that are associated with the engine. They include (not a full list):

ABS, Glow Plugs, ECU, Horn, Foglights, Washer Pump, Engine Cooling Fans, Cab Heater Fan, Main Beam

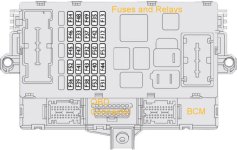

The Under Dash Fuses B002 are mostly for things associated with the body. They include:

Instrument Panel, BCM, Electric Windows, Central Locking, Cigar Lighter, Brake Lights, Reversing Lights, Wipers, Dip Beam

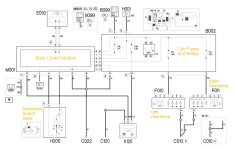

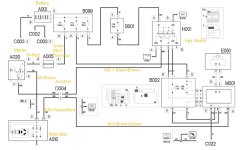

As you have misbehaviour from several "customers" of the under dash fuses B002, I am wondering if there is a problem with the live feed to B002. It is supplied from F71, which is an 80A maxi fuse situated on the small panel on the battery positive terminal. A thick red wire runs from here to B002, where it joins with a nut and bolt. I suggest you check out F71 and the connections at each end of the thick red cable. If there is excessive resistance, as soon as you start to draw appreciable current the voltage will drop down, which may make the BCM play up. I also suggest you check out the 10A fuse F38 in B002, which feeds the BCM, as if it has a poor connection this too could starve the BCM of power. Of course, it could all be fine and the BCM is the culprit, but worth eliminating as a possibility.

Just for completeness, the engine bay fuses B001 are supplied in a similar fashion but from F70, which is a 150A fuse. Another thick red wire runs to B001.

Its normal for lights to be a little brighter when you rev up from idling, as the battery voltage will climb a little when the alternator is charging more. This effect will be more pronounced if the battery is in need of a charge. A check with a voltmeter directly on the battery terminals is the best test. You should see something like 12.5 volts when the battery has been sat unused for a while and nothing is switched on. Once the engine has started, this will climb to something like 14 to 14.5 volts as the alternator does its stuff.