In the past I would definitely say ignition switch fault from those symptoms and even today with all the electronics , I would test that area first with a multimeter.Hi again I have a 2014 3.0 Conversion I love

Remember My van will not shut off even when I take the key out. It will start and it runs good but when you go to shut it off nothing happens all the dashboard panels lights are out, it just won't stop running.

1. Engine won't switch off normal, Built you turn the key from off to on very slightly as if turning on, the engine shuts down.

3. There is a battery draw when the key is off or when the key in the half- on position that stop the motor.

4. Several relays under the hood and other things our clicking all at the same time on and off with no steady pattern when the key is off

or in the half position.

5 Disconnected all non factory wiring.

Maybe ???

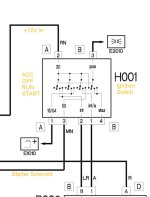

ECU RELAY

ECU

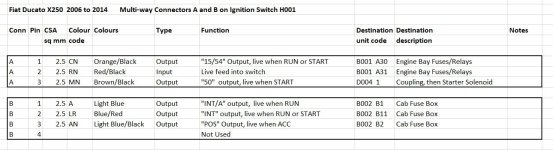

key switch

You could try some proper electronics switch cleaner spray which dries out to nothing leaving no residue (unlike WD40 types) in and around the ignition switch whilst working it several times with battery disconnected, then when dry see if it has changed the situation.

Last edited: