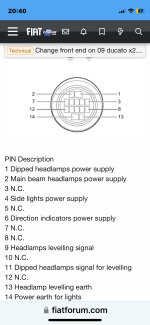

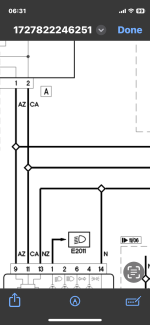

I'd rather use automotive connectors, but wago is good.

T-type (perhaps it's called differently in English, sorry) allows you to connect three wires together.

This type is crap, because it can cut the wire

So the link is just to show the idea.

The ones on the attached screenshot are much better.

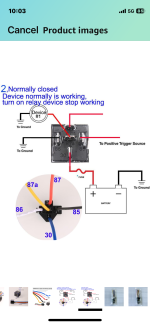

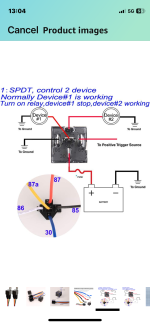

You need only one relay to connect both DRLs.

The connection I described above is my idea how I would do that, I have not tested it before, as I have the classical x250 headlights.

The description how to wire DRLs with the relay has been tested and works fine as requested by the EU regulations.

So first connect everything outside of the vehicle to test, but cut the wires and add connectors only after confirming that everything works fine. And disconnect the battery before you start

T-type (perhaps it's called differently in English, sorry) allows you to connect three wires together.

This type is crap, because it can cut the wire

So the link is just to show the idea.

The ones on the attached screenshot are much better.

You need only one relay to connect both DRLs.

The connection I described above is my idea how I would do that, I have not tested it before, as I have the classical x250 headlights.

The description how to wire DRLs with the relay has been tested and works fine as requested by the EU regulations.

So first connect everything outside of the vehicle to test, but cut the wires and add connectors only after confirming that everything works fine. And disconnect the battery before you start