Can you show a top view of the head just out of interestI've taken the plunge and removed the cylinder head. It all looks OK, save for the poor condition of one of the spark plug threads.

View attachment 439217

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Technical Cam shaft replacement - is it an engine out job?

- Thread starter smart51

- Start date

Currently reading:

Technical Cam shaft replacement - is it an engine out job?

Is the damaged spark plug thread going to be repaired by a Helicoil (or similar) thread insert, or is it still good enough?I've taken the plunge and removed the cylinder head. It all looks OK, save for the poor condition of one of the spark plug threads.

smart51

Established member

Can you show a top view of the head just out of interest

Is there something in particular you want to see?

smart51

Established member

There are 3 good threads left. It might be a good idea to get it done.Is the damaged spark plug thread going to be repaired by a Helicoil (or similar) thread insert, or is it still good enough?

I was interested to see the size of the inlet port and as to whether it was 26mm like the 500 or 30mm like the later 126. Looks to be 30mm to me, thank you

smart51

Established member

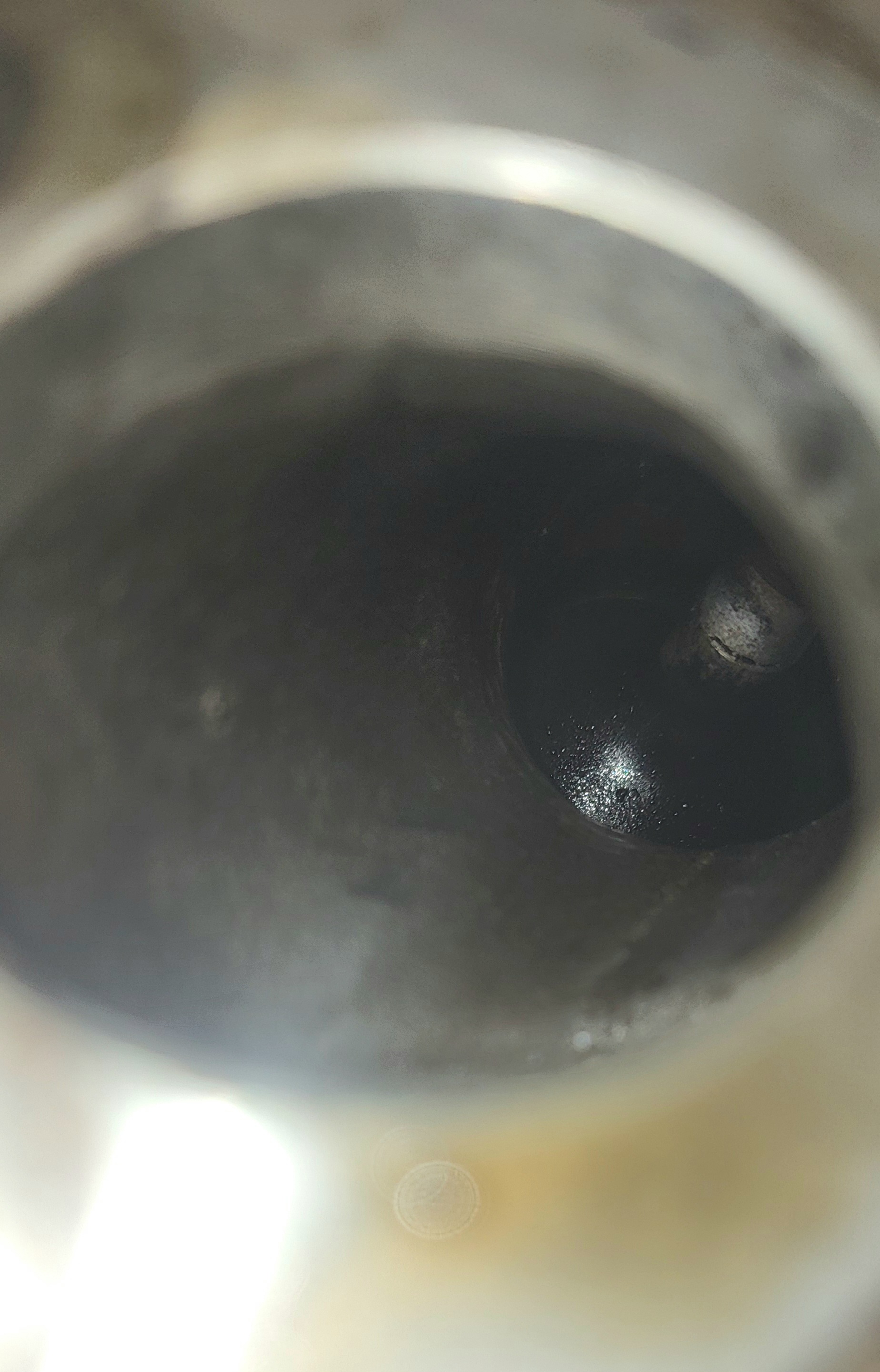

People talk about easing a ridge in the inlet tract of the cylinder head to aid air flow. Mine feels quite smooth. Here's a photo showing the back of an inlet valve through the carb inlet. Where is this ridge?

the hobbler

Distinguished member

- Joined

- Jul 25, 2012

- Messages

- 4,362

- Points

- 1,096

If you put your finger into the inlet tract though the VALVE aperture, you will feel distinct ridge just inside the valve seat. Yes,it will be 'smooth', but it needs to be 'softened' quite a bit,which really only be done with a finger and various grades of emery-cloth. Remenber, the walls of the inlet tract only needs to be smoothish. SLIGHT roughness helps to actually increase flow. The exhaust tract needs to be polished.People talk about easing a ridge in the inlet tract of the cylinder head to aid air flow. Mine feels quite smooth. Here's a photo showing the back of an inlet valve through the carb inlet. Where is this ridge?

View attachment 439233

smart51

Established member

Day 2 and I'm trying to remove the camshaft. If pulls out by 20mm then there is a thunk and if won't go any further. It will turn freely but there is something in its way.

I've pulled the fuel pump rod and the distributor. What else do I need to remove?

I've pulled the fuel pump rod and the distributor. What else do I need to remove?

smart51

Established member

All outPush rod tubes and cam followers ?

smart51

Established member

It was the crank counter weight. A small rotation of the crank and the cam came right out.

3 of the lobes are worn down to 5.8mm of lift, 0.4mm less than the spec. The No1 exhaust cam is worn down to 5.1mm of lift, down 1.1mm! Not only the lobe, but both sides were shiny metal. The shoulders of the other 3 lobes were still black with the metal just showing through in the middle.

3 of the lobes are worn down to 5.8mm of lift, 0.4mm less than the spec. The No1 exhaust cam is worn down to 5.1mm of lift, down 1.1mm! Not only the lobe, but both sides were shiny metal. The shoulders of the other 3 lobes were still black with the metal just showing through in the middle.

the hobbler

Distinguished member

- Joined

- Jul 25, 2012

- Messages

- 4,362

- Points

- 1,096

That would seemto be the cause of your lack of performance! If you can afford it, I would suggest that (if the engine doesn't already have them) that you replace the 'concertina' push-rod tubes with 'spring-loaded' tubes. The last longer, are not so prone to leak (thinner 'spring' section goes to the top) and the head is easier to fit when using the 'spring loaded' tubes. They will compress enough that you can fit the head, do the head-stud nuts up a couple of turns and THEN insert the tubes---an easy one man jobIt was the crank counter weight. A small rotation of the crank and the cam came right out.

3 of the lobes are worn down to 5.8mm of lift, 0.4mm less than the spec. The No1 exhaust cam is worn down to 5.1mm of lift, down 1.1mm! Not only the lobe, but both sides were shiny metal. The shoulders of the other 3 lobes were still black with the metal just showing through in the middle.

smart51

Established member

Are these the right seals for the push rod tubes? They seem very big to me.

smart51

Established member

I'm rebuilding the engine and have these two odd washers left in the box that had all the cowling hardware in it. Can you remind me where they're from please?

They go on the small studs securing the thermostat housing to the cylinder head adjacent Tto the exhaust elbows.I'm rebuilding the engine and have these two odd washers left in the box that had all the cowling hardware in it. Can you remind me where they're from please?

View attachment 439600

smart51

Established member

It lives. All is well. I'd knocked the 12v wire off the ballast resistor, but once fixed, it started and ran.

It sounds a bit different now, perhaps a bit more gruff. It sounds a lot happier below 2000 RPM, though doesn't pull any better down there. It idles more cleanly too.

I've taken is for a gentle test drive to warm it all up. Tomorrow I'll check all the nuts and bolts once it's cooled down.

It sounds a bit different now, perhaps a bit more gruff. It sounds a lot happier below 2000 RPM, though doesn't pull any better down there. It idles more cleanly too.

I've taken is for a gentle test drive to warm it all up. Tomorrow I'll check all the nuts and bolts once it's cooled down.

Last edited:

smart51

Established member

To answer my original question - is cam shaft replacement an engine out job? No. I wouldn't even have thought it was so tricky that the extra work of removing the engine would have been offset by making it simpler. It was quite a lot of work, but none of it very complicated.

smart51

Established member

Well this has stopped being fun. Slowing down for a roundabout on a dual carriageway, there was a big bang and a flapping noise. One of the spark plugs has popped out of the head. It was about 300m from a Harvester. I managed to start it on 1 cylinder and coax if off the dual carriageway. I'm now waiting for the RAC.

I'd spotted that the threads were weak and bought a helicoil kit. When it arrived, the spark plugs fitted inside the helicoils with room to spade, I ordered an M12 kit as a replacement. These were way too tight, but had the right size tap to clean up the threads so I settled for that. Big mistake. So the head has to come off and be fixed up. Still, worse places to be broken down.

Edited for posterity. Both helicoil kits were junk. The tap and pilot drill was correct but the coils were way off size.

I'd spotted that the threads were weak and bought a helicoil kit. When it arrived, the spark plugs fitted inside the helicoils with room to spade, I ordered an M12 kit as a replacement. These were way too tight, but had the right size tap to clean up the threads so I settled for that. Big mistake. So the head has to come off and be fixed up. Still, worse places to be broken down.

Edited for posterity. Both helicoil kits were junk. The tap and pilot drill was correct but the coils were way off size.

Last edited:

smart51

Established member

The RAC man suggested tapping the head to M14 x 1.25 and fit a larger spark plug, rather than have an M12 x 1.25 helicoil fitted. What would you do?

edited to say that the spark plugs are M14 x 1.25 and that the junk helicoil kits I bought led me to belive otherwise.

edited to say that the spark plugs are M14 x 1.25 and that the junk helicoil kits I bought led me to belive otherwise.

Last edited:

Similar threads

- Replies

- 9

- Views

- 129

- Replies

- 1

- Views

- 174