as long as the crank pulley is the same, all is good

Its not the same as my two spi crank pulleys, maybe its just the altinator pulley that looks different, or im just being silly

as long as the crank pulley is the same, all is good

indeed, the crank pulley looks different.

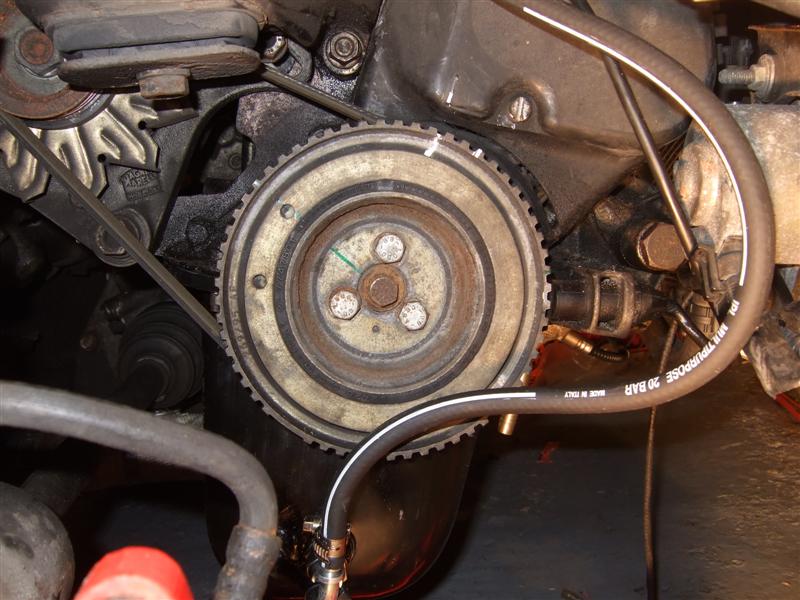

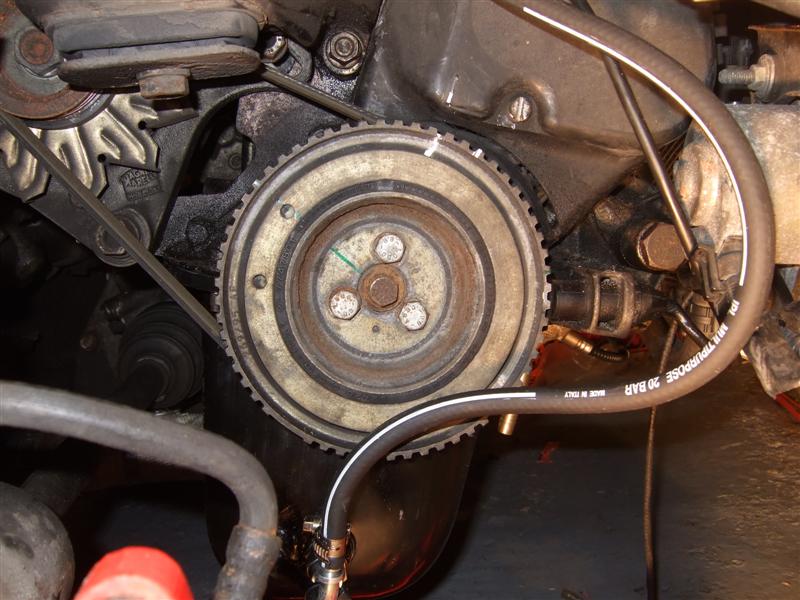

this is what mine looks like

Well, you can't see the crank cog as its hidden behing the pulley

The pulley on the 1.2 is different to the 1.1. The timing teeth on the alterntor pulley sit on the outside of the pulley, and the crank sensor sits further out to compensate.

You can swap the pulley around for any you like though if you move the sensor, the bolt holes are the same. My 16v has the 1.1 alternator pulley bolted to the 16v crank, with a bracket shifting the sensor out.

Shame I can't see arc's picture at the minute. Work is blocking his site

Kristian

trying to keep things rolling along steadily so bits don't get left out until the last minute

wonder why it blocked my site, i took the pictures of boobs off there