Richenrygarcia

New member

- Joined

- Jan 29, 2016

- Messages

- 86

- Points

- 25

Hello all. While enjoying a leisurely drive yesterday a grinding noise

erupted from the Cinquecento, and the stopped moving. Drive to the

wheel(s) had been lost but the motor continued to run. I thought the car

had "popped" out of gear but this wasn't the case. I was able to coast the

car to a safe stop, out of the way.

The gear selector works just fine. I can shift thought all 4 gears and put

it in neutral. When I put it in gear, release the clutch and press the

accelerator pedal, the grinding noise starts again.

I'm hoping a drive shaft coupling joint has stripped its splines as this is

an easier fix that opening the gearbox. Can anyone tell me how to determine

if this is the problem before I remove the hubs? Also, how easy are the

drive shaft coupling joints to remove and replace? The Haynes manual is

vague about the process and describes a means to determine bearing pre-load which isn’t very clear either.

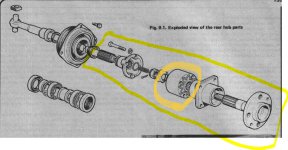

Please see the attachment. The part highlighted in yellow is where I hope t he problem lies and the circled part is where I think the part which may have failed. I’m only thinking this because I’ve heard these parts are prone to failure and, at this point, don’t want to think about a bigger problem with the transmission.

erupted from the Cinquecento, and the stopped moving. Drive to the

wheel(s) had been lost but the motor continued to run. I thought the car

had "popped" out of gear but this wasn't the case. I was able to coast the

car to a safe stop, out of the way.

The gear selector works just fine. I can shift thought all 4 gears and put

it in neutral. When I put it in gear, release the clutch and press the

accelerator pedal, the grinding noise starts again.

I'm hoping a drive shaft coupling joint has stripped its splines as this is

an easier fix that opening the gearbox. Can anyone tell me how to determine

if this is the problem before I remove the hubs? Also, how easy are the

drive shaft coupling joints to remove and replace? The Haynes manual is

vague about the process and describes a means to determine bearing pre-load which isn’t very clear either.

Please see the attachment. The part highlighted in yellow is where I hope t he problem lies and the circled part is where I think the part which may have failed. I’m only thinking this because I’ve heard these parts are prone to failure and, at this point, don’t want to think about a bigger problem with the transmission.