Confortmatic as in thread title.

so i'm expected to actualy read things properly,

So being a comfortmatic there are a number of this that can/ need to be done with

multiecuscan

eg

Clutch calibration

This procedure is used for the fine calibration of the clutch. It must be performed if the actuation unit and/or clutch assembly is replaced, if the clutch engages and disengages in an uneven way and if the gearbox control unit is replaced.

The following is necessary for proper execution of this procedure:

- engine temperature > 80°C

- clutch temperature between 20°C and 150°C

- no errors

NOTE: The procedure must be performed in the following sequence:

1. Press the Execute button (engine must be OFF - Stop&Start function not active, gear in Neutral)

2. Start the engine

3. Wait! The control unit will perform 5 clutch activation cycles! It should finish in ~1 minute.

4. Turn the key OFF, then wait at least 15 seconds and turn the key to MAR.

this example is for 2.3 x290 others may be different

what model have you got

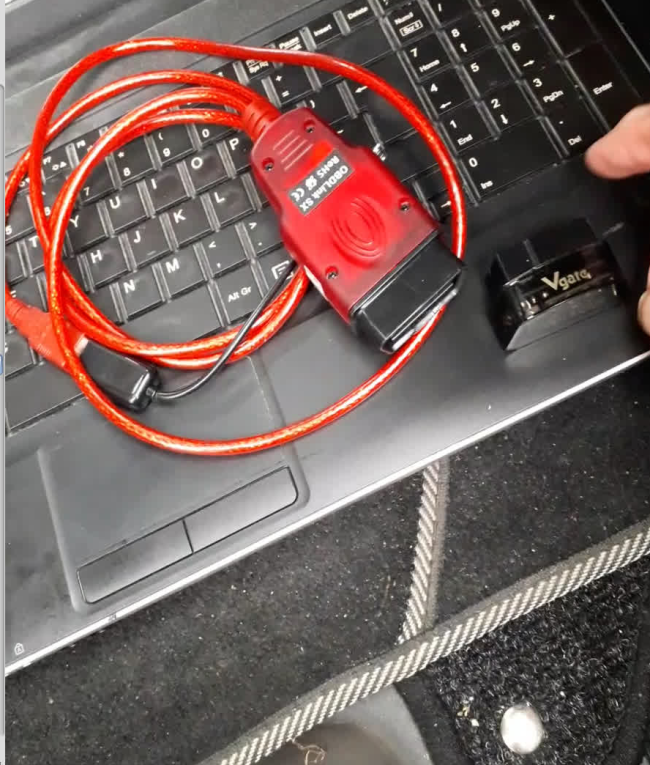

This a much bigger question than first appears. If we limit it to what is a cost effective DIY solution to "read my Fiat and simple maintenance issues eg change the oil in my euro 6 or add a new MAF sensor" then the answer for me reduces to...

www.fiatforum.com

Extracted from something I downloaded thinking it may be useful, not my original work.

Working on the Comfortmatic gear change system

If you have a catastrophic component failure and mechanical works need to be undertaken then it is necessary to perform some routines to safely undertake the works and then setup the system once reassembled.

Multiecuscan (

MES) has all the necessary routines.

You need to run the 'accumulator depressurization' routine in

MES to safely reduce the hydraulic oil pressure in the Comfortmatic module before any works are undertaken.

Undertake the mechanical works in the same way as the manual gearchange. Gearbox out, change CSC, clutch and DMF (if necessary).Reassemble everything including adding hydraulic oil and gravity bleeding the clutch.

1. Run the 'clutch and electropump replacement' routines in

MES to reset the Transmission Control Unit (TCU) electronics.

2 Run 'actuator base adjustment' in

MES to setup the hydraulic and clutch units.

3. Run the 'clutch drain' routine in

MES to ensure there is no air in the clutch system.

4 Run 'clutch self-calibration enable' in

MES to fine tune the clutch actuation to engine specific behaviour.