So, you just "went for it" and hit the starter without turning the engine by hand first? You're a much braver (and by the sound of it luckier) man than I! As has been said, the later engines - and that's definitely the ones with the Variator sprocket - are interference so you have been lucky! Always turn the engine over, gently, by hand, for at least two crank shaft revolutions before hitting the start button so you can feel if anything (ie pistons and valves) are making contact.

Here's a picture of the locking tool kit I bought which works on all the 8 valve engines but not the 16 valve ones (although it says on the cover label that it does!)

The bright metal bar on the right is the cam locking tool. You have to remove the cam cover (older people will call it a rocker cover) to gain access as it engages with a slot in the other end of the camshaft to the sprocket. Here it is bolted in place on "Becky's" 60HP engine.

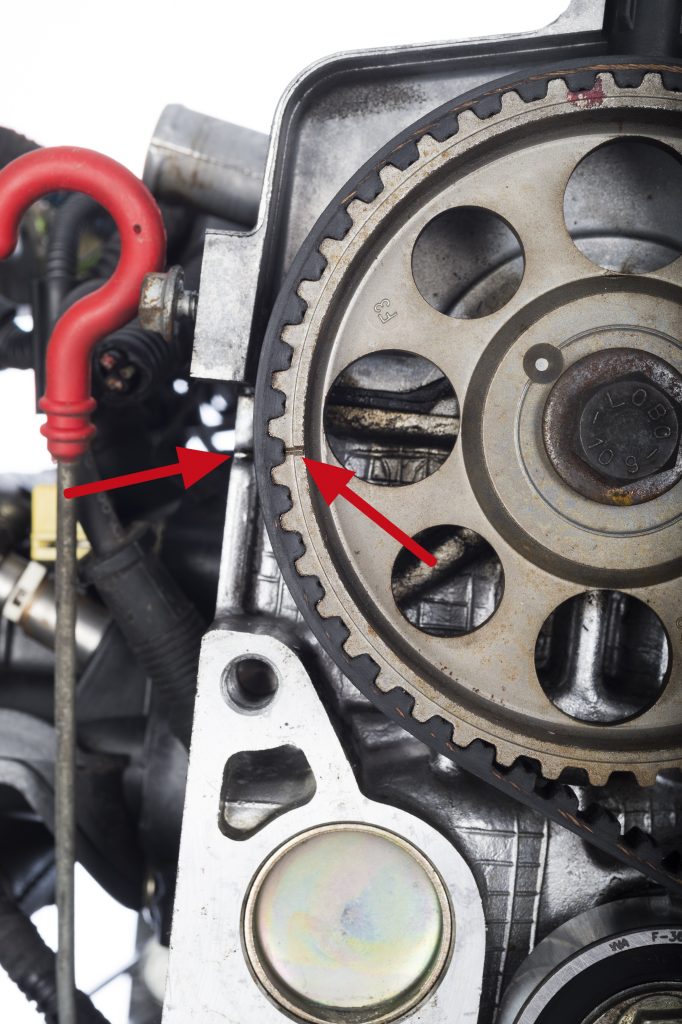

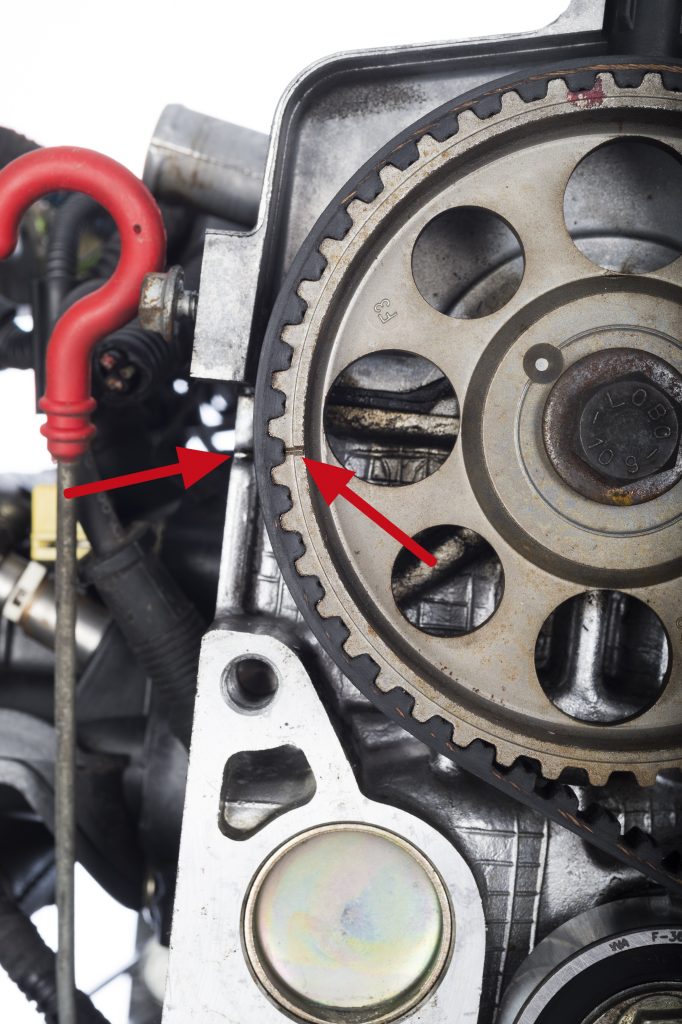

Also in the first picture you can see a large black fixture on the left which is the crank shaft locking tool. Here it is on Becky.

You will also need the small black tool with the silver colored bolt (top right) which is used to immobilise the sprocket whilst you tighten it's securing bolt (and it goes up very tight!). By the way the small tool with a hole in it, just to the left of the sprocket tool, is my home made flywheel locking tool and not a standard part of the kit. I wouldn't trust the kit's crank locking tool, which "hangs" on a 6mm bolt, to hold when trying to slacken the crank sprocket bolt - which you will need to do if the oil seal were to need replacing.

I've been thinking about your situation. As I understand it you didn't slacken the cam sprocket bolt (and why would you if you didn't know the recommended proceedure) but you took the cam belt off without marking anything up? So now you have an engine which is technically untimed with no marks to enable you to time it up again. And, on your later model engine, in danger of possibly suffering valve/piston contact if the crankshaft is turned!

You could, in theory, time it up by removing the spark plugs and, very gently, rotating the crankshaft, either clockwise or anticlockwise, feeling for valve contact all the time, until the pistons are all half way up (or down, if you like to think of it that way) the bores, and so nowhere near the valves. Now you can safely turn the camshaft until either No1 or No4 cylinder's valves are in overlap (that is to say "on the rock" with the exhaust just closing and the inlet just opening) the other cylinder will have both valves closed. Now gently turn the crankshaft to TDC on 1 and 4 and try refitting the belt. I think you should be able to get to within half a tooth so fitting the belt correctly should be possible. Of course, after tensioning the belt and checking nothing has moved (make temporary marks on sprockets and engine) you should still turn the engine over at least twice (so cam goes one complete rev) to check there is no piston/valve contact. This is quite risky stuff if you have little experience as it's not easy to accurately establish true TDC on an engine with no timing marks. also some engines do not have their inlet and exhaust valves opening and closing at the same no of degrees before and after TDC/BDC so some intelligent thought and past experience helps a lot. It doesn't matter if you choose to time it up on No1 or No4 as the ignition system picks up it's position from the sensor on the end of the camshaft so it knows which cylinder to fire (although the timing trigger is the crankshaft sensor).

Need I say that this all puts your engine at some risk if you don't really know what you're doing so don't try it unless you feel confident in your ability and fully understand the risks - the bill could be huge if you get it wrong!

Hope you found that interresting? If any of you more experienced chaps want to contradict or correct me please feel free. I'm always up for gaining knowledge.

Kindest regards

Jock