Getting it up in the air cheaply:

Ok, let's get started. First thing to mention is, if you don't need to take the wheels off for the task you're undertaking how about finding a nice high street curb and just sticking two wheels up on it:

Be aware some local regulations forbid parking on pavements though. To gain even more space get a piece of 4x4 fence post or old railway sleeper and chamfer down one end so you can drive up it then place it so the other front wheel drives up onto it as you mount the curb with the other as seen here.

When I was at college and living in digs with hardly two pennies to rub together I, and my college mates, would do oil and filter changes, check and change gearbox oil, even done a few clutches on things like Anglias and Cortinas - you go under feet first and, when everything is undone you rest the gearbox tail shaft on your knees and lift the bellhousing down with your hands. Definitely need to be young and healthy for that though. Of course it's no good if you want to do brake work or anything for which the wheels have to come off. Also, on more modern vehicles, getting at the fixings for the engine undercover can be problematic with the wheels still on. However if you're just doing simple stuff like oil changes then it's worth a thought. At college we had an unofficial list of where the highest curbs were!

If the above does well enough for you then you might like to consider a set of ramps. They will achieve the same result and possibly give you a bit more height but the great thing about them is you're not going to find someone parked beside the very bit of nice high curb you were hoping to make yours for the weekend. Here's the Ibiza up on mine:

One wee word of warning though. check the actual ramps you are thinking of buying against the car itself. Some slope so steeply the ramp hits the car's front bumper before the wheels can start climbing the ramp. Mine were like this but were Ok for the older cars I worked on back in those days. I welded extensions to them, roughly doubling the length of the angled section, so I could use them on m odern cars with their greater front overhangs.

This is where I'd like to go to a new page, but I don't know how so we'll just continue.

So you want to do tasks the ramps won't allow? Ok, now we need to raise the vehicle with a jack so we can take the wheels off - By the way remember to slacken wheel bolts/nuts by about a quarter to half a turn BEFORE raising the vehicle while the wheel is still being prevented from turning by the fact it's still on the ground (unless you've got a nice powerful air or electric impact wrench)

DO NOT WORK ON AN UNSTABLE SURFACE. JACKS AND AXLE STANDS CAN AND DO TILT AND LET THE VEHICLE FALL. Anyway, it's pretty unpleasant lying on your back in the mud or on sharp stones/pebbles! So you need to be on a paved road, concrete or slabbed surface. Personally I don't like block pavers because they have so many joints a trolley jack's wheels can get stuck. If I have to work where the surface isn't smooth I have a substantial sheet of steel which I put under the jack to let the wheels turn easily. This is important because a trolley jack needs to "walk" forward as the arm lifts the vehicle. If it can't and the other side is already up on a stand, you might drag the vehicle off the stand.

First off lets look at where it's safest to position a jack. Most modern cars have sections of their sills which are reinforced specifically to allow for jacking. Many will actually have a mark on the sill to guide you. Here's the mark on my Panda's sill:

If you look under the sill at the "pinch" seam, you'll see it's just a little thicker:

This is intended to accept the jack supplied with the vehicle - more on them in a minute - which, in this case, has a top shaped like this:

Which engages with the sill seam like so:

Now, there's something important to notice here, which is that the weight is not being taken on the pinch seam itself but actually on either side where the sill and floor is reinforced. How often do you see tyre fitters with a trolley jack, usually without even a rubber pad to protect the paint, and applying the load directly to the pinch seam itself - no wonder so many are damaged and folded over and starting to "fester" with rust as a result!

So that's got the wheel off the ground, using just what came with the car, at no additional cost. However there are dangers in this which we'll now think about on the next page.

Be aware some local regulations forbid parking on pavements though. To gain even more space get a piece of 4x4 fence post or old railway sleeper and chamfer down one end so you can drive up it then place it so the other front wheel drives up onto it as you mount the curb with the other as seen here.

When I was at college and living in digs with hardly two pennies to rub together I, and my college mates, would do oil and filter changes, check and change gearbox oil, even done a few clutches on things like Anglias and Cortinas - you go under feet first and, when everything is undone you rest the gearbox tail shaft on your knees and lift the bellhousing down with your hands. Definitely need to be young and healthy for that though. Of course it's no good if you want to do brake work or anything for which the wheels have to come off. Also, on more modern vehicles, getting at the fixings for the engine undercover can be problematic with the wheels still on. However if you're just doing simple stuff like oil changes then it's worth a thought. At college we had an unofficial list of where the highest curbs were!

If the above does well enough for you then you might like to consider a set of ramps. They will achieve the same result and possibly give you a bit more height but the great thing about them is you're not going to find someone parked beside the very bit of nice high curb you were hoping to make yours for the weekend. Here's the Ibiza up on mine:

One wee word of warning though. check the actual ramps you are thinking of buying against the car itself. Some slope so steeply the ramp hits the car's front bumper before the wheels can start climbing the ramp. Mine were like this but were Ok for the older cars I worked on back in those days. I welded extensions to them, roughly doubling the length of the angled section, so I could use them on m odern cars with their greater front overhangs.

This is where I'd like to go to a new page, but I don't know how so we'll just continue.

So you want to do tasks the ramps won't allow? Ok, now we need to raise the vehicle with a jack so we can take the wheels off - By the way remember to slacken wheel bolts/nuts by about a quarter to half a turn BEFORE raising the vehicle while the wheel is still being prevented from turning by the fact it's still on the ground (unless you've got a nice powerful air or electric impact wrench)

DO NOT WORK ON AN UNSTABLE SURFACE. JACKS AND AXLE STANDS CAN AND DO TILT AND LET THE VEHICLE FALL. Anyway, it's pretty unpleasant lying on your back in the mud or on sharp stones/pebbles! So you need to be on a paved road, concrete or slabbed surface. Personally I don't like block pavers because they have so many joints a trolley jack's wheels can get stuck. If I have to work where the surface isn't smooth I have a substantial sheet of steel which I put under the jack to let the wheels turn easily. This is important because a trolley jack needs to "walk" forward as the arm lifts the vehicle. If it can't and the other side is already up on a stand, you might drag the vehicle off the stand.

First off lets look at where it's safest to position a jack. Most modern cars have sections of their sills which are reinforced specifically to allow for jacking. Many will actually have a mark on the sill to guide you. Here's the mark on my Panda's sill:

If you look under the sill at the "pinch" seam, you'll see it's just a little thicker:

This is intended to accept the jack supplied with the vehicle - more on them in a minute - which, in this case, has a top shaped like this:

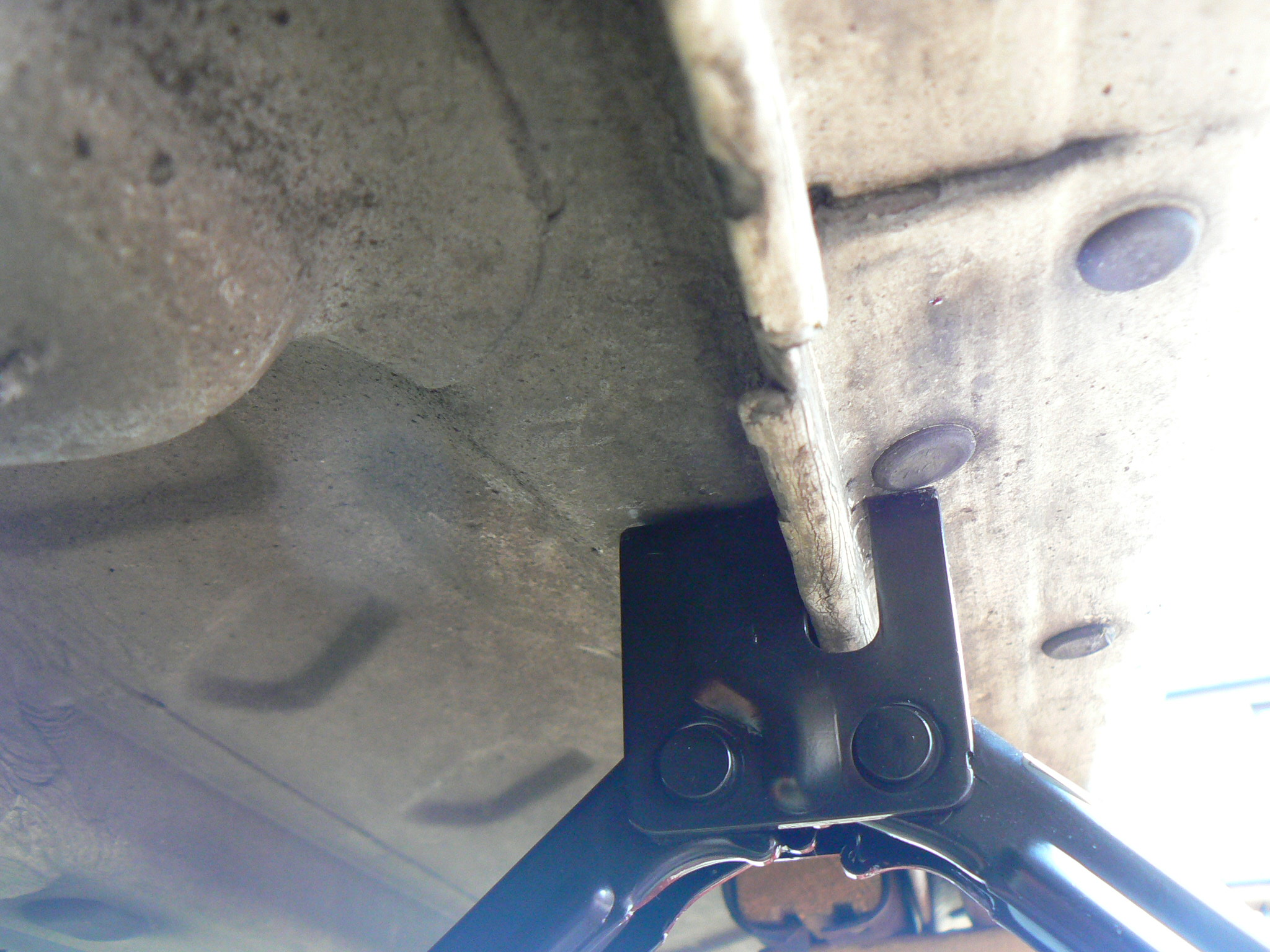

Which engages with the sill seam like so:

Now, there's something important to notice here, which is that the weight is not being taken on the pinch seam itself but actually on either side where the sill and floor is reinforced. How often do you see tyre fitters with a trolley jack, usually without even a rubber pad to protect the paint, and applying the load directly to the pinch seam itself - no wonder so many are damaged and folded over and starting to "fester" with rust as a result!

So that's got the wheel off the ground, using just what came with the car, at no additional cost. However there are dangers in this which we'll now think about on the next page.