I recently posted some stuff on jacking and axle stand use in the thread "What's needed to run Multiecuscan" and several people "liked" it and Herts Hillhopper said he thought it should be moved to the guides section. I took another look at it but decided it was somewhat lacking and decided to do this here instead.

Before I start here's the usual disclaimer: This post is intended primarily to make people think about staying safe when raising and supporting their car. Hopefully it'll also be of use to those who are less experienced and with little training in this area. It's not intended as a definitive guide to be taken literally and in every situation because individual makes and models of car vary so much. In other words, if you are in any doubt at all about what you are going to do, then don't do it. NEVER EVER HAVE ANY PART OF YOUR BODY UNDER A VEHICLE SUPPORTED ONLY BY A JACK. If it falls on you it's a very nasty painful way to die!

Before I start here's the usual disclaimer: This post is intended primarily to make people think about staying safe when raising and supporting their car. Hopefully it'll also be of use to those who are less experienced and with little training in this area. It's not intended as a definitive guide to be taken literally and in every situation because individual makes and models of car vary so much. In other words, if you are in any doubt at all about what you are going to do, then don't do it. NEVER EVER HAVE ANY PART OF YOUR BODY UNDER A VEHICLE SUPPORTED ONLY BY A JACK. If it falls on you it's a very nasty painful way to die!

Getting it up in the air cheaply:

Ok, let's get started. First thing to mention is, if you don't need to take the wheels off for the task you're undertaking how about finding a nice high street curb and just sticking two wheels up on it:

Be aware some local regulations forbid parking on pavements though. To gain even more space get a piece of 4x4 fence post or old railway sleeper and chamfer down one end so you can drive up it then place it so the other front wheel drives up onto it as you mount the curb with the other as seen here.

When I was at college and living in digs with hardly two pennies to rub together I, and my college mates, would do oil and filter changes, check and change gearbox oil, even done a few clutches on things like Anglias and Cortinas - you go under feet first and, when everything is undone you rest the gearbox tail shaft on your knees and lift the bellhousing down with your hands. Definitely need to be young and healthy for that though. Of course it's no good if you want to do brake work or anything for which the wheels have to come off. Also, on more modern vehicles, getting at the fixings for the engine undercover can be problematic with the wheels still on. However if you're just doing simple stuff like oil changes then it's worth a thought. At college we had an unofficial list of where the highest curbs were!

If the above does well enough for you then you might like to consider a set of ramps. They will achieve the same result and possibly give you a bit more height but the great thing about them is you're not going to find someone parked beside the very bit of nice high curb you were hoping to make yours for the weekend. Here's the Ibiza up on mine:

One wee word of warning though. check the actual ramps you are thinking of buying against the car itself. Some slope so steeply the ramp hits the car's front bumper before the wheels can start climbing the ramp. Mine were like this but were Ok for the older cars I worked on back in those days. I welded extensions to them, roughly doubling the length of the angled section, so I could use them on m odern cars with their greater front overhangs.

This is where I'd like to go to a new page, but I don't know how so we'll just continue.

So you want to do tasks the ramps won't allow? Ok, now we need to raise the vehicle with a jack so we can take the wheels off - By the way remember to slacken wheel bolts/nuts by about a quarter to half a turn BEFORE raising the vehicle while the wheel is still being prevented from turning by the fact it's still on the ground (unless you've got a nice powerful air or electric impact wrench)

DO NOT WORK ON AN UNSTABLE SURFACE. JACKS AND AXLE STANDS CAN AND DO TILT AND LET THE VEHICLE FALL. Anyway, it's pretty unpleasant lying on your back in the mud or on sharp stones/pebbles! So you need to be on a paved road, concrete or slabbed surface. Personally I don't like block pavers because they have so many joints a trolley jack's wheels can get stuck. If I have to work where the surface isn't smooth I have a substantial sheet of steel which I put under the jack to let the wheels turn easily. This is important because a trolley jack needs to "walk" forward as the arm lifts the vehicle. If it can't and the other side is already up on a stand, you might drag the vehicle off the stand.

First off lets look at where it's safest to position a jack. Most modern cars have sections of their sills which are reinforced specifically to allow for jacking. Many will actually have a mark on the sill to guide you. Here's the mark on my Panda's sill:

If you look under the sill at the "pinch" seam, you'll see it's just a little thicker:

This is intended to accept the jack supplied with the vehicle - more on them in a minute - which, in this case, has a top shaped like this:

Which engages with the sill seam like so:

Now, there's something important to notice here, which is that the weight is not being taken on the pinch seam itself but actually on either side where the sill and floor is reinforced. How often do you see tyre fitters with a trolley jack, usually without even a rubber pad to protect the paint, and applying the load directly to the pinch seam itself - no wonder so many are damaged and folded over and starting to "fester" with rust as a result!

So that's got the wheel off the ground, using just what came with the car, at no additional cost. However there are dangers in this which we'll now think about on the next page.

Be aware some local regulations forbid parking on pavements though. To gain even more space get a piece of 4x4 fence post or old railway sleeper and chamfer down one end so you can drive up it then place it so the other front wheel drives up onto it as you mount the curb with the other as seen here.

When I was at college and living in digs with hardly two pennies to rub together I, and my college mates, would do oil and filter changes, check and change gearbox oil, even done a few clutches on things like Anglias and Cortinas - you go under feet first and, when everything is undone you rest the gearbox tail shaft on your knees and lift the bellhousing down with your hands. Definitely need to be young and healthy for that though. Of course it's no good if you want to do brake work or anything for which the wheels have to come off. Also, on more modern vehicles, getting at the fixings for the engine undercover can be problematic with the wheels still on. However if you're just doing simple stuff like oil changes then it's worth a thought. At college we had an unofficial list of where the highest curbs were!

If the above does well enough for you then you might like to consider a set of ramps. They will achieve the same result and possibly give you a bit more height but the great thing about them is you're not going to find someone parked beside the very bit of nice high curb you were hoping to make yours for the weekend. Here's the Ibiza up on mine:

One wee word of warning though. check the actual ramps you are thinking of buying against the car itself. Some slope so steeply the ramp hits the car's front bumper before the wheels can start climbing the ramp. Mine were like this but were Ok for the older cars I worked on back in those days. I welded extensions to them, roughly doubling the length of the angled section, so I could use them on m odern cars with their greater front overhangs.

This is where I'd like to go to a new page, but I don't know how so we'll just continue.

So you want to do tasks the ramps won't allow? Ok, now we need to raise the vehicle with a jack so we can take the wheels off - By the way remember to slacken wheel bolts/nuts by about a quarter to half a turn BEFORE raising the vehicle while the wheel is still being prevented from turning by the fact it's still on the ground (unless you've got a nice powerful air or electric impact wrench)

DO NOT WORK ON AN UNSTABLE SURFACE. JACKS AND AXLE STANDS CAN AND DO TILT AND LET THE VEHICLE FALL. Anyway, it's pretty unpleasant lying on your back in the mud or on sharp stones/pebbles! So you need to be on a paved road, concrete or slabbed surface. Personally I don't like block pavers because they have so many joints a trolley jack's wheels can get stuck. If I have to work where the surface isn't smooth I have a substantial sheet of steel which I put under the jack to let the wheels turn easily. This is important because a trolley jack needs to "walk" forward as the arm lifts the vehicle. If it can't and the other side is already up on a stand, you might drag the vehicle off the stand.

First off lets look at where it's safest to position a jack. Most modern cars have sections of their sills which are reinforced specifically to allow for jacking. Many will actually have a mark on the sill to guide you. Here's the mark on my Panda's sill:

If you look under the sill at the "pinch" seam, you'll see it's just a little thicker:

This is intended to accept the jack supplied with the vehicle - more on them in a minute - which, in this case, has a top shaped like this:

Which engages with the sill seam like so:

Now, there's something important to notice here, which is that the weight is not being taken on the pinch seam itself but actually on either side where the sill and floor is reinforced. How often do you see tyre fitters with a trolley jack, usually without even a rubber pad to protect the paint, and applying the load directly to the pinch seam itself - no wonder so many are damaged and folded over and starting to "fester" with rust as a result!

So that's got the wheel off the ground, using just what came with the car, at no additional cost. However there are dangers in this which we'll now think about on the next page.

Raising the vehicle

On the last page we were using the car's own jack to raise it. There's a problem with using these jacks which come with the car. There are many slightly different designs but they all have one inherent problem which is they are not very stable. Here's some typical ones:

The black one is the Pandas original and intended for the car. The red one is a generic one bought off the internet. Notice the saddle which contacts the car will not work how it's meant to as the weight will be taken on the sill seam and the "claws" are likely to scratch the paint off. The last one, at the bottom of the picture is from the Ibiza and you can see it has quite a nice nylon insert to minimize paint damage to the sill. All have one big problem though. they have just one "foot" so have no inherent stability. If the car moves it'll fall off the jack. Then, especially if you've got the wheel off, you've got a very real problem because how do you lift it back up when it's flush with the ground and you can't get the jack back under it? Better for this situation not to arise at all so, Always chock the wheels. Of course you've got the handbrake on tightly haven't you? If you're just changing a puncture then chock the wheel diagonally opposite the one you're working on - so if you're working on the O/S front then chock the N/S rear, and chock it both in front and behind. with a bit of luck that will stop it rolling forward or backwards but it won't do anything to stabilize it sideways. Be aware that as you jack up one wheel the other one on that end of the vehicle will also be experiencing weight removed from it. So if you're jacking up the O/S front then the N/S will also rise as you jack and this reduces the load on the N/S wheel and the ability of the tyre on that side to grip the road/ground. Jack it high enough and the car will move sideways and fall off the jack so only ever jack up high enough to get the new wheel on. A "nasty" aspect of this is that if we consider the above scenario, ie. O/S/F being jacked up, and the N/S/F is on an unstable surface like gravel, mud, even a slimy, perhaps mossy, surface, then the N/S/F tyre will loose it's grip and the car will fall sideways off the jack. So, only jack up on a sound surface. Keep in mind also that a flat tyre will have a flat bottom - if you see what I mean - so if you just jack up far enough to remove the punctured wheel you won't be able to get the spare on without winding the jack up a bit further. It's better to get all the jacking done in one as operating the jack is when it's most likely to fall over.

A lot of this problem can be alleviated by using a trolley jack which is much more stable. I'll come back to trolley jacks in a while. Bottle jacks or similar aren't really a "goer" for this sort of thing and are also pretty unstable.

Here's a couple of trolley jacks with home made sill protecting pads on their "business" ends. You can buy commercially made protective "pucks" which are made from hard rubber with a slot in the middle to protect the sill seam.

The smaller jack is in use here and you can see it's managing to lift the car just far enough to get the stand underneath on pretty much it's lowest position. This is quite enough to be doing brake work though - as you can see the wheel is well clear of the ground. Sometimes, like working on exhausts etc, you need more height when something, like the red jack, will be needed. Here's three representative examples:

The one nearest to us is my friend's with a total lift of 390 mm which gets the axle stands up to a bit above the first hole but not high enough to get the pin in the second hole. Next is my very old friend, first trolley jack I ever bought and now sporting a new pumping element (the red bit) as the original wore out and started leaking. He has a lift of 415 mm and can get the car up high enough to get the pin in the second hole on the axle stand. The big red one is another old friend which I've had for so long they don't make that model any more and he can get the axle stands up to full height with a lift of 500 mm. I find working with my friend's jack a little limiting due to it's lift restriction. Also you may notice it gets that lift at the cost of it's closed height - look at the saddle and you'll see it's higher from the arm compared to both of mine. It's not quite so good for going under low vehicles for this reason. It's lifting arm is 220 mm long compared with my wee one's 270 mm. So mine starts off lower but still achieves a higher lift ultimately. For years I worked at home with just this jack and found it worked well for most jobs.

The black one is the Pandas original and intended for the car. The red one is a generic one bought off the internet. Notice the saddle which contacts the car will not work how it's meant to as the weight will be taken on the sill seam and the "claws" are likely to scratch the paint off. The last one, at the bottom of the picture is from the Ibiza and you can see it has quite a nice nylon insert to minimize paint damage to the sill. All have one big problem though. they have just one "foot" so have no inherent stability. If the car moves it'll fall off the jack. Then, especially if you've got the wheel off, you've got a very real problem because how do you lift it back up when it's flush with the ground and you can't get the jack back under it? Better for this situation not to arise at all so, Always chock the wheels. Of course you've got the handbrake on tightly haven't you? If you're just changing a puncture then chock the wheel diagonally opposite the one you're working on - so if you're working on the O/S front then chock the N/S rear, and chock it both in front and behind. with a bit of luck that will stop it rolling forward or backwards but it won't do anything to stabilize it sideways. Be aware that as you jack up one wheel the other one on that end of the vehicle will also be experiencing weight removed from it. So if you're jacking up the O/S front then the N/S will also rise as you jack and this reduces the load on the N/S wheel and the ability of the tyre on that side to grip the road/ground. Jack it high enough and the car will move sideways and fall off the jack so only ever jack up high enough to get the new wheel on. A "nasty" aspect of this is that if we consider the above scenario, ie. O/S/F being jacked up, and the N/S/F is on an unstable surface like gravel, mud, even a slimy, perhaps mossy, surface, then the N/S/F tyre will loose it's grip and the car will fall sideways off the jack. So, only jack up on a sound surface. Keep in mind also that a flat tyre will have a flat bottom - if you see what I mean - so if you just jack up far enough to remove the punctured wheel you won't be able to get the spare on without winding the jack up a bit further. It's better to get all the jacking done in one as operating the jack is when it's most likely to fall over.

A lot of this problem can be alleviated by using a trolley jack which is much more stable. I'll come back to trolley jacks in a while. Bottle jacks or similar aren't really a "goer" for this sort of thing and are also pretty unstable.

Here's a couple of trolley jacks with home made sill protecting pads on their "business" ends. You can buy commercially made protective "pucks" which are made from hard rubber with a slot in the middle to protect the sill seam.

The smaller jack is in use here and you can see it's managing to lift the car just far enough to get the stand underneath on pretty much it's lowest position. This is quite enough to be doing brake work though - as you can see the wheel is well clear of the ground. Sometimes, like working on exhausts etc, you need more height when something, like the red jack, will be needed. Here's three representative examples:

The one nearest to us is my friend's with a total lift of 390 mm which gets the axle stands up to a bit above the first hole but not high enough to get the pin in the second hole. Next is my very old friend, first trolley jack I ever bought and now sporting a new pumping element (the red bit) as the original wore out and started leaking. He has a lift of 415 mm and can get the car up high enough to get the pin in the second hole on the axle stand. The big red one is another old friend which I've had for so long they don't make that model any more and he can get the axle stands up to full height with a lift of 500 mm. I find working with my friend's jack a little limiting due to it's lift restriction. Also you may notice it gets that lift at the cost of it's closed height - look at the saddle and you'll see it's higher from the arm compared to both of mine. It's not quite so good for going under low vehicles for this reason. It's lifting arm is 220 mm long compared with my wee one's 270 mm. So mine starts off lower but still achieves a higher lift ultimately. For years I worked at home with just this jack and found it worked well for most jobs.

Supporting safely.

This means axle stands. However I usually leave the jack under the sill and/or slide the wheel under the sill when I've removed it from the vehicle. Anything handy which will stop the vehicle coming down and crushing me! Don't take a chance on bricks, breeze blocks or other such solutions. Not stable or strong, they can crumble.

So, Axle stands? We're talking about these things:

Over the years I've collected 3 pairs and I'm showing you two here. I like the sort that has removable pins like you see here. You can buy a type with different pin design but I just don't like them. I prefer the simplicity and inherent safety of a simple pin. Also worth noting is the large foot size on the left couple. The one's on the right, you'll notice, has much narrower feet. The ones on the left are the first ones I bought - back when I was in college - I welded the larger feet onto the ones on the left because in hot summer weather I found the straight angle iron ends would sink into the tarmac if I had to leave a car up on them for more than a few hours. Now that I work mostly on concrete or slabs I never bothered making feet for the yellow ones.

Now we've got some stands how do we use them? This is the bit everyone gets a bit nervous about. Choose the wrong place to site them and you can seriously damage or even wreck a car.

Lets look under the Panda - this is the FIAT Forum after all!

We've looked at jacking points on the sills but the stands can't easily be located there, or if you do you're likely to damage the seam or paintwork and also sills are notorious for rusting so better left alone. All right we're talking about box sections here These are reinforced "boxed" structures which give the car's structure strength. Here's a few examples:

N/S (passenger side) just inboard of the sill - you can see the back end of the front sub frame on the left of the picture where it bolts to the box section:

Longitudinal (front to rear) just behind the previous example:

And now at the rear, just in front of the rear wheel:

These structures are all repeated on the other side - O/S - of the vehicle.

Before positioning a stand and letting the car's weight be taken on it, do a visual examination for rust etc. If badly rusted it'll probably be incapable of supporting the car's weight. Then you've got a problem because it's going to fail it's MOT so that needs to be fixed first.

If all looks good then get a wee bit of wood and place it on the top of your axle stand - this helps protect the vehicles paint/underseal and also tends to stop the stand slipping as the metal of the car tends to bite into the wood.

Here's one located under the first image of a box section shown above. We're looking from the front of the vehicle now, under the engine:

So, if we put another in the same place on the other side and pull back a bit, it looks like this:

Oh dear! have you noticed my "deliberate" mistake? Yes, that's it, I haven't put any chocks behind the back wheels have I? Ok, let's sort that:

My driveway slopes slightly away from the house so blocks behind the wheels works well. on the flat you might want to put chocks both in front of and behind the wheels which are not in the air.

Chocks? what chocks? Well, as I used here, some bits of 2x4 work well enough but I also carry a set of red collapsible chocks in the Panda and yellow fixed ones in the Ibiza, as here:

The yellow chocks were actually part of the wheel changing kit in a Datsun I owned, which I thought was a nice touch. Notice the bit of wood under the jack? It's a thick piece of marine 14 ply just in case I'm forced to attempt a puncture change on a less than perfect surface so the jack doesn't sink into the ground - actually never needed to use it.

You can also support the vehicle on the subframe if you think the box sections are too weak to take it. Here's the Panda supported on her front subframe:

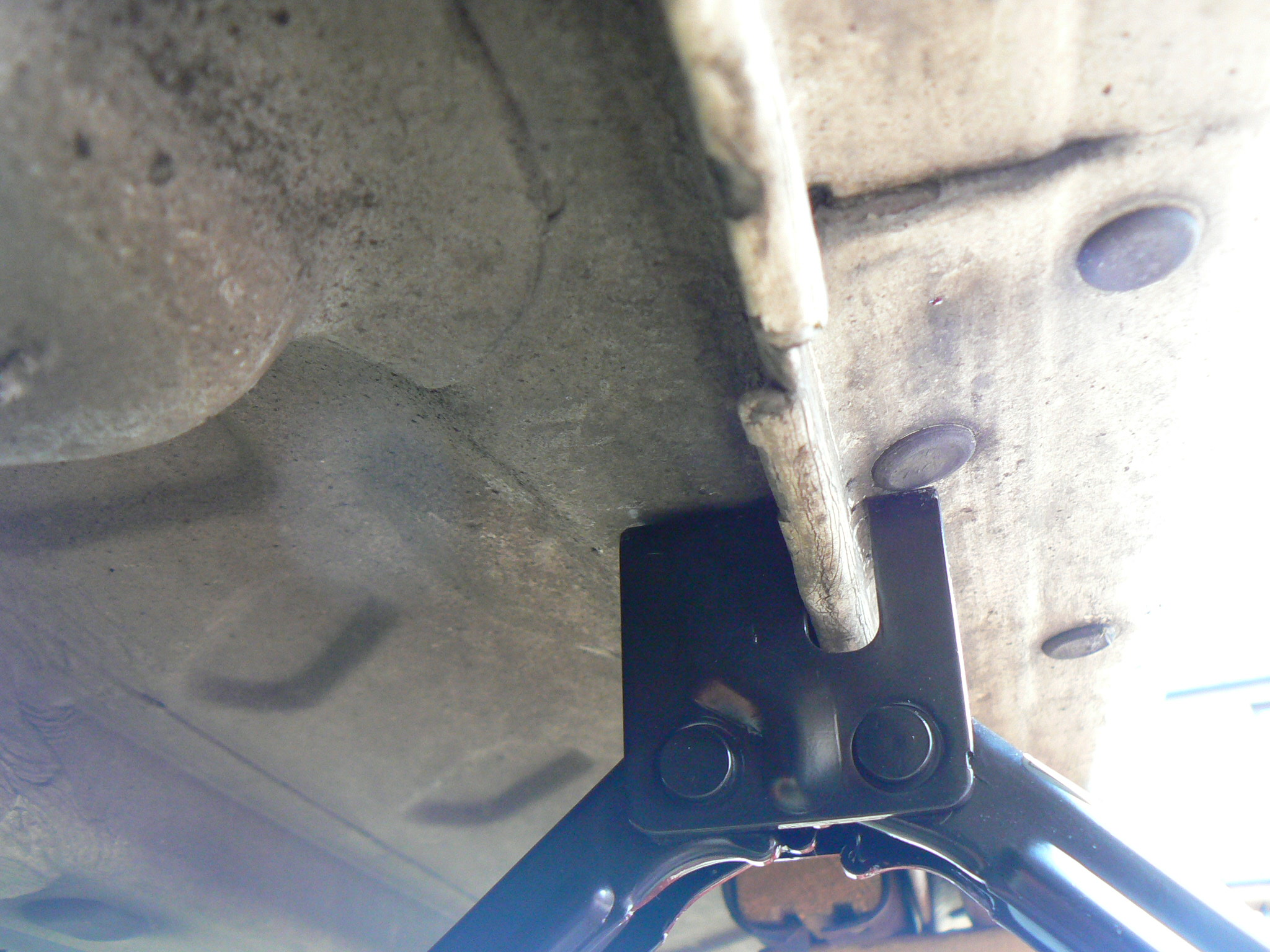

These subframes are usually pretty strong but, if you're going to do it this way then try to position the stand so the weight is born up through the subframe mounting vertically to the vehicle structure. It's not too clear in the above picture but look here and you'll get a better idea what I'm talking about:

At the bottom you can see the saddle of the stand with it's bit of wood and above it the subframe sitting on it with, at the top of the picture the subframe mounting bolt holding it to the car's body. You can see the forces are acting pretty much vertically up into that mounting bolt - very unlikely anything will get deformed.

At the rear we have similar box sections and you can use the stand on them in the same way:

If you're going up a lot in height it's best to go in stages. Maybe half way on one side, position the axle stand and then do the other side before coming back to the first side and going up to the full height. If you're going to attempt to take all four wheels off the ground be very careful what you're doing as it's very easy to destabilize the whole thing with disastrous consequences. Better to work on one side or one end at a time, so no more than two wheels up at any time. I also don't believe in jacking up in the middle of the rear axle. People have done it and suffered no consequences, but if you bend the axle it means the rear geometry will be compromised and a new axle is really the only way to sort the problem properly. Even more importantly never try to jack the car up under the sump. It's just not designed to take the entire weight of the front of the car and even quite a small deformation can have serious consequences. It's very likely the oil pickup will be obstructed if you deform the bottom of the sump which could lead to premature engine failure later

What I've been talking about above can be carried over to most modern cars. Take a look at the Ibiza's nether regions:

This picture was taken whilst she was up on the ramps I mentioned at the beginning and you can see how good the access is using them - of course you wouldn't be putting it up on the ramps if you were intending to use the stands. The engine subframe can be clearly seen and the same logic applies - look for where it's bolted to the body structure and put the axle stands, or jack, under there. On this one the square holes you can see (sorry, the one on the right is obscured by that blob of rain water on the lens) are actually the bottom of the vertical element that bolts to the body frame work. You can see all the plastic cladding along the bottom of the car? luckily it doesn't obstruct the bodywork box sections at the front of the sills so I've got good access there for jack or stands if I want. Some modern cars have so much of this plastic cladding you're toiling to find a solid place for stands or jacks.

So, Axle stands? We're talking about these things:

Over the years I've collected 3 pairs and I'm showing you two here. I like the sort that has removable pins like you see here. You can buy a type with different pin design but I just don't like them. I prefer the simplicity and inherent safety of a simple pin. Also worth noting is the large foot size on the left couple. The one's on the right, you'll notice, has much narrower feet. The ones on the left are the first ones I bought - back when I was in college - I welded the larger feet onto the ones on the left because in hot summer weather I found the straight angle iron ends would sink into the tarmac if I had to leave a car up on them for more than a few hours. Now that I work mostly on concrete or slabs I never bothered making feet for the yellow ones.

Now we've got some stands how do we use them? This is the bit everyone gets a bit nervous about. Choose the wrong place to site them and you can seriously damage or even wreck a car.

Lets look under the Panda - this is the FIAT Forum after all!

We've looked at jacking points on the sills but the stands can't easily be located there, or if you do you're likely to damage the seam or paintwork and also sills are notorious for rusting so better left alone. All right we're talking about box sections here These are reinforced "boxed" structures which give the car's structure strength. Here's a few examples:

N/S (passenger side) just inboard of the sill - you can see the back end of the front sub frame on the left of the picture where it bolts to the box section:

Longitudinal (front to rear) just behind the previous example:

And now at the rear, just in front of the rear wheel:

These structures are all repeated on the other side - O/S - of the vehicle.

Before positioning a stand and letting the car's weight be taken on it, do a visual examination for rust etc. If badly rusted it'll probably be incapable of supporting the car's weight. Then you've got a problem because it's going to fail it's MOT so that needs to be fixed first.

If all looks good then get a wee bit of wood and place it on the top of your axle stand - this helps protect the vehicles paint/underseal and also tends to stop the stand slipping as the metal of the car tends to bite into the wood.

Here's one located under the first image of a box section shown above. We're looking from the front of the vehicle now, under the engine:

So, if we put another in the same place on the other side and pull back a bit, it looks like this:

Oh dear! have you noticed my "deliberate" mistake? Yes, that's it, I haven't put any chocks behind the back wheels have I? Ok, let's sort that:

My driveway slopes slightly away from the house so blocks behind the wheels works well. on the flat you might want to put chocks both in front of and behind the wheels which are not in the air.

Chocks? what chocks? Well, as I used here, some bits of 2x4 work well enough but I also carry a set of red collapsible chocks in the Panda and yellow fixed ones in the Ibiza, as here:

The yellow chocks were actually part of the wheel changing kit in a Datsun I owned, which I thought was a nice touch. Notice the bit of wood under the jack? It's a thick piece of marine 14 ply just in case I'm forced to attempt a puncture change on a less than perfect surface so the jack doesn't sink into the ground - actually never needed to use it.

You can also support the vehicle on the subframe if you think the box sections are too weak to take it. Here's the Panda supported on her front subframe:

These subframes are usually pretty strong but, if you're going to do it this way then try to position the stand so the weight is born up through the subframe mounting vertically to the vehicle structure. It's not too clear in the above picture but look here and you'll get a better idea what I'm talking about:

At the bottom you can see the saddle of the stand with it's bit of wood and above it the subframe sitting on it with, at the top of the picture the subframe mounting bolt holding it to the car's body. You can see the forces are acting pretty much vertically up into that mounting bolt - very unlikely anything will get deformed.

At the rear we have similar box sections and you can use the stand on them in the same way:

If you're going up a lot in height it's best to go in stages. Maybe half way on one side, position the axle stand and then do the other side before coming back to the first side and going up to the full height. If you're going to attempt to take all four wheels off the ground be very careful what you're doing as it's very easy to destabilize the whole thing with disastrous consequences. Better to work on one side or one end at a time, so no more than two wheels up at any time. I also don't believe in jacking up in the middle of the rear axle. People have done it and suffered no consequences, but if you bend the axle it means the rear geometry will be compromised and a new axle is really the only way to sort the problem properly. Even more importantly never try to jack the car up under the sump. It's just not designed to take the entire weight of the front of the car and even quite a small deformation can have serious consequences. It's very likely the oil pickup will be obstructed if you deform the bottom of the sump which could lead to premature engine failure later

What I've been talking about above can be carried over to most modern cars. Take a look at the Ibiza's nether regions:

This picture was taken whilst she was up on the ramps I mentioned at the beginning and you can see how good the access is using them - of course you wouldn't be putting it up on the ramps if you were intending to use the stands. The engine subframe can be clearly seen and the same logic applies - look for where it's bolted to the body structure and put the axle stands, or jack, under there. On this one the square holes you can see (sorry, the one on the right is obscured by that blob of rain water on the lens) are actually the bottom of the vertical element that bolts to the body frame work. You can see all the plastic cladding along the bottom of the car? luckily it doesn't obstruct the bodywork box sections at the front of the sills so I've got good access there for jack or stands if I want. Some modern cars have so much of this plastic cladding you're toiling to find a solid place for stands or jacks.

Final words

Get this wrong and there's lots of ways you can do serious damage to yourself or your car. Just don't get under any car supported on a jack - any jack - unless backed up with supplementary support - like axle stands etc. I've seen plenty of evidence by way of distorted floor panels, damaged suspension parts and even one where the floor had been pushed up because someone tried to support the car by corroded floor panels. Look carefully for weakness caused by rust and whatever you're doing, do it slowly. I mean jack it up slowly and as the weight is taken listen for scrunchy crackling noises which might indicate a rusty part is failing. similar advice after you've placed the axle stands, Let the pressure off the jack very slowly and look and listen attentively as they take the weight. If the seats start going up inside the car you've got a big problem!

Never jack in the middle of the rear axle or under the engine sump.

Just take it slowly until you really get a feel for it and never ever take anything for granted. Above all, never let anyone stay in the vehicle while you're working on it. This is especially true if doing a roadside wheel change using the supplied "suicide" jack where even quite a small movement inside the car might cause it to destabilize and fall off the jack. This can be hard if it's a nasty day but you'll all really regret it if you're stuck with a car on it's belly and you've got to wait maybe hours for a breakdown recovery vehicle.

Never jack in the middle of the rear axle or under the engine sump.

Just take it slowly until you really get a feel for it and never ever take anything for granted. Above all, never let anyone stay in the vehicle while you're working on it. This is especially true if doing a roadside wheel change using the supplied "suicide" jack where even quite a small movement inside the car might cause it to destabilize and fall off the jack. This can be hard if it's a nasty day but you'll all really regret it if you're stuck with a car on it's belly and you've got to wait maybe hours for a breakdown recovery vehicle.