Yesterday we started work on fitting the low boost Van Aaken kit to burple!

Pulling her cover off David mutters " hello burple...*sigh*" old friends re-united

The first job was to fit the new oil pump to the 1242 i have, as it was cracked. this part was smooth sailing, but David kept jinxing it by saying how well it was going

at this point my step mum made us all lunch and it was yummy! :yum:

So the time came to fit the modified sump..... no fitty!

Burple hadn't been on form as had been sleeping, hence allowing the oil pump to go so well, but now she was awake tried her very hardest to make the jobs as difficult as possible!

i'm sure it was at this point she bit him, bloody spoiled car...

ok moving on... next job was to refit the new turbo i had bought to the origional manifold ( which had the origional turbo still attatched) but we noticed that the new turbo, albeit the exact same... some parts of it sat at different angles, tried to change it - but it will need a little more dedication.

Next was a trial fit to see how it all went together and more specifically if a spacer was going to be needed since its a 1242. By jings it isnt half a tight squeeze getting that turbo in there - will need to find out what your supposed to do with the water pipes!

aye spacer needed, so that's job number 3.

and just to add the icing to the cake -a little sensor got snapped

so the balls rolling - just need to sort out some of the little glitches to get it going.

on the plus side the kit looks amazing, so shiny and awesome :worship:

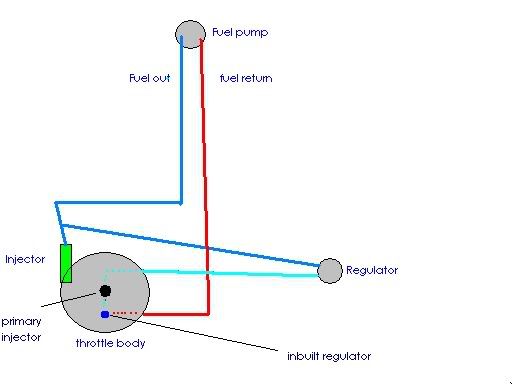

Oh - is there any destructions on how to wire up the mf2 and fcd? and the perks of my job meant i could ultrasonically clean the injector

and the perks of my job meant i could ultrasonically clean the injector

so thanks to David ( spd) for agreeing to climb this lil mountain - im sure its a decision he'l live to regret

and to dave (red-tjet - not the bunny one )for the pics!

)for the pics!

Dont remember what i was looking for

shiny!

wheelies!!!

Pulling her cover off David mutters " hello burple...*sigh*" old friends re-united

The first job was to fit the new oil pump to the 1242 i have, as it was cracked. this part was smooth sailing, but David kept jinxing it by saying how well it was going

at this point my step mum made us all lunch and it was yummy! :yum:

So the time came to fit the modified sump..... no fitty!

Burple hadn't been on form as had been sleeping, hence allowing the oil pump to go so well, but now she was awake tried her very hardest to make the jobs as difficult as possible!

i'm sure it was at this point she bit him, bloody spoiled car...

ok moving on... next job was to refit the new turbo i had bought to the origional manifold ( which had the origional turbo still attatched) but we noticed that the new turbo, albeit the exact same... some parts of it sat at different angles, tried to change it - but it will need a little more dedication.

Next was a trial fit to see how it all went together and more specifically if a spacer was going to be needed since its a 1242. By jings it isnt half a tight squeeze getting that turbo in there - will need to find out what your supposed to do with the water pipes!

aye spacer needed, so that's job number 3.

and just to add the icing to the cake -a little sensor got snapped

so the balls rolling - just need to sort out some of the little glitches to get it going.

on the plus side the kit looks amazing, so shiny and awesome :worship:

Oh - is there any destructions on how to wire up the mf2 and fcd?

so thanks to David ( spd) for agreeing to climb this lil mountain - im sure its a decision he'l live to regret

and to dave (red-tjet - not the bunny one

Dont remember what i was looking for

shiny!

wheelies!!!