Just when I thought I had it sorted (and the engine is running really well now) I have dug up some more confusing information.

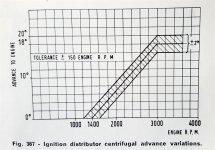

The first is that on the post 1985 engine, the manual gives three positions for checking the timing:

1. @ 700 rpm = 10 BTDC

2. @ 3000rpm = 14 BTDC

3. @ 3850rpm = 21 BTDC

I can now use the strobe but have no way to check those rpm's accurately.

The second thing is that the 123 ignition manual:

http://www.123ignition.nl/pdf/FIAT2R.pdf

states that timing should be

1. @2000 rpm = 16 BTDC

2. 3000 rpm = 28 BTDC

This seems very contradictory and confusing.

I have set mine at 18 BTDC on very fast revs. It runs and starts well but has anyone actually set the 123 as described?

The final thing is that there is a setting 1. on the distributor for "idle control". What is that and is it any advantage to me?

The first is that on the post 1985 engine, the manual gives three positions for checking the timing:

1. @ 700 rpm = 10 BTDC

2. @ 3000rpm = 14 BTDC

3. @ 3850rpm = 21 BTDC

I can now use the strobe but have no way to check those rpm's accurately.

The second thing is that the 123 ignition manual:

http://www.123ignition.nl/pdf/FIAT2R.pdf

states that timing should be

1. @2000 rpm = 16 BTDC

2. 3000 rpm = 28 BTDC

This seems very contradictory and confusing.

I have set mine at 18 BTDC on very fast revs. It runs and starts well but has anyone actually set the 123 as described?

The final thing is that there is a setting 1. on the distributor for "idle control". What is that and is it any advantage to me?