Ok, another busy week / weekend and almost done on the front of the sill / wheel arch area.

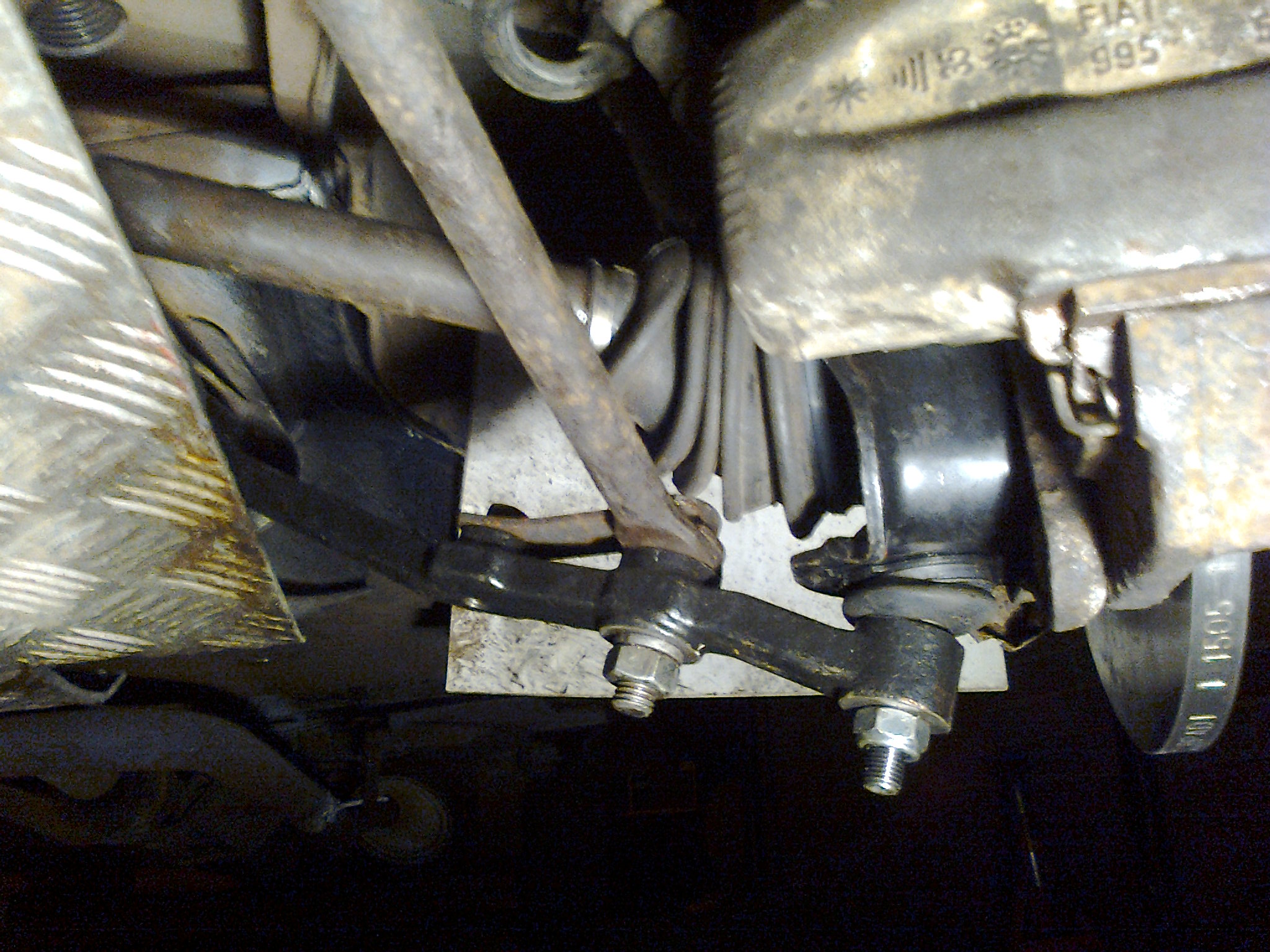

Had to repair the seam before I could add the repair patch...something the MOT place in Swansea didn't do first time round...

A difficult place to weld though...narrow space and upwards...great for setting fire to your clothes

Then it was the outer sill which I patched up with reasonable success...

Still a big hole on the inner sill though

...

So one more patch later and looking a bit more promising. Welding here was a bit poop though as the welder developed a wire delivery fault and a gas leak

but beginning to show some structure again...

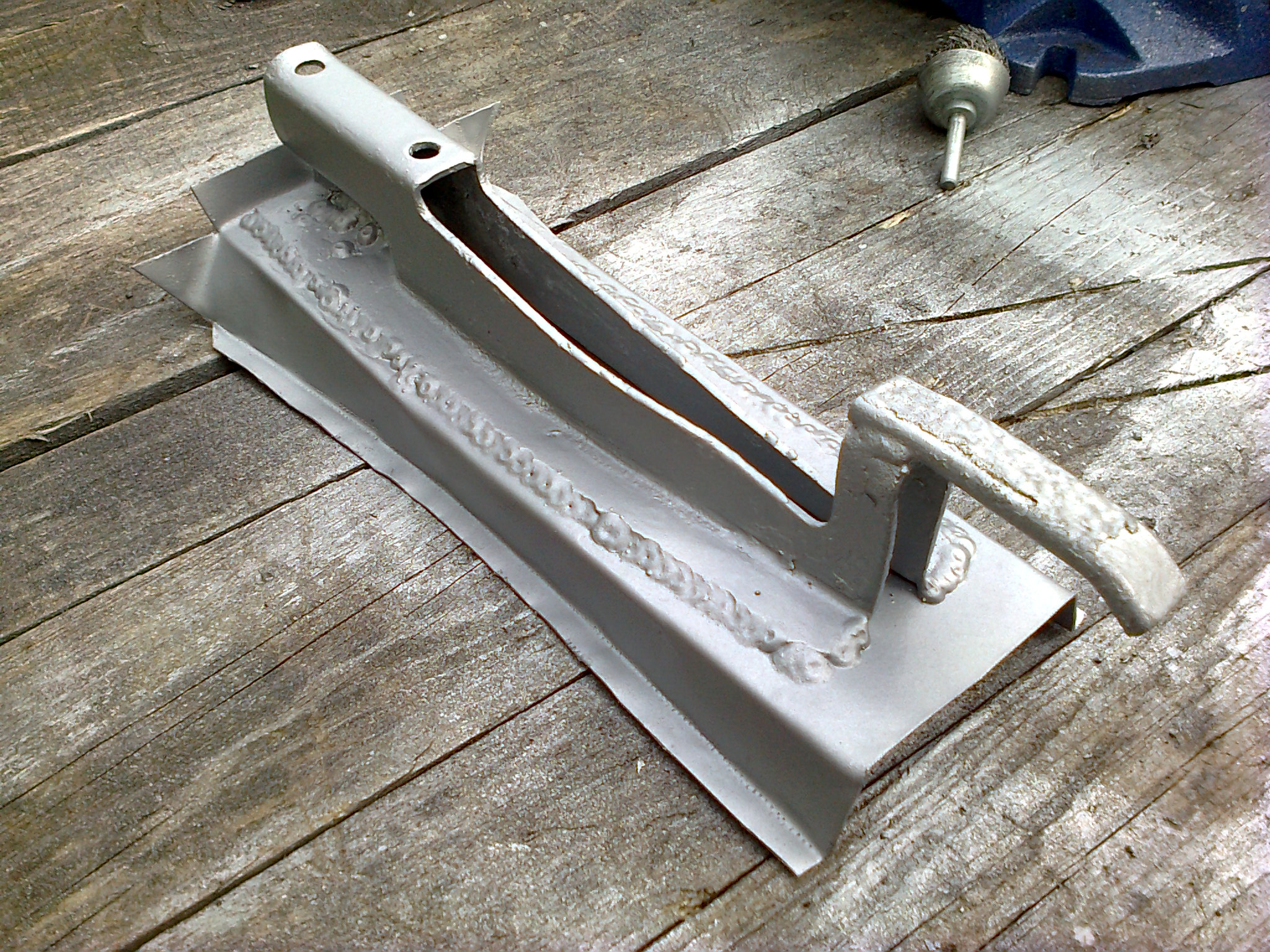

Next job was re-constructing the jacking point. This was so badly corroded I had to do lots of repairs to it before it could even go back onto the car...

But before I could fix the jacking point to the car I had to rebuild the box section it sat on

so fabricated this little jobby...:slayer:

And then welded the jacking point to it before going on the car so I could respray the welds from the other side with zinc paint and primer

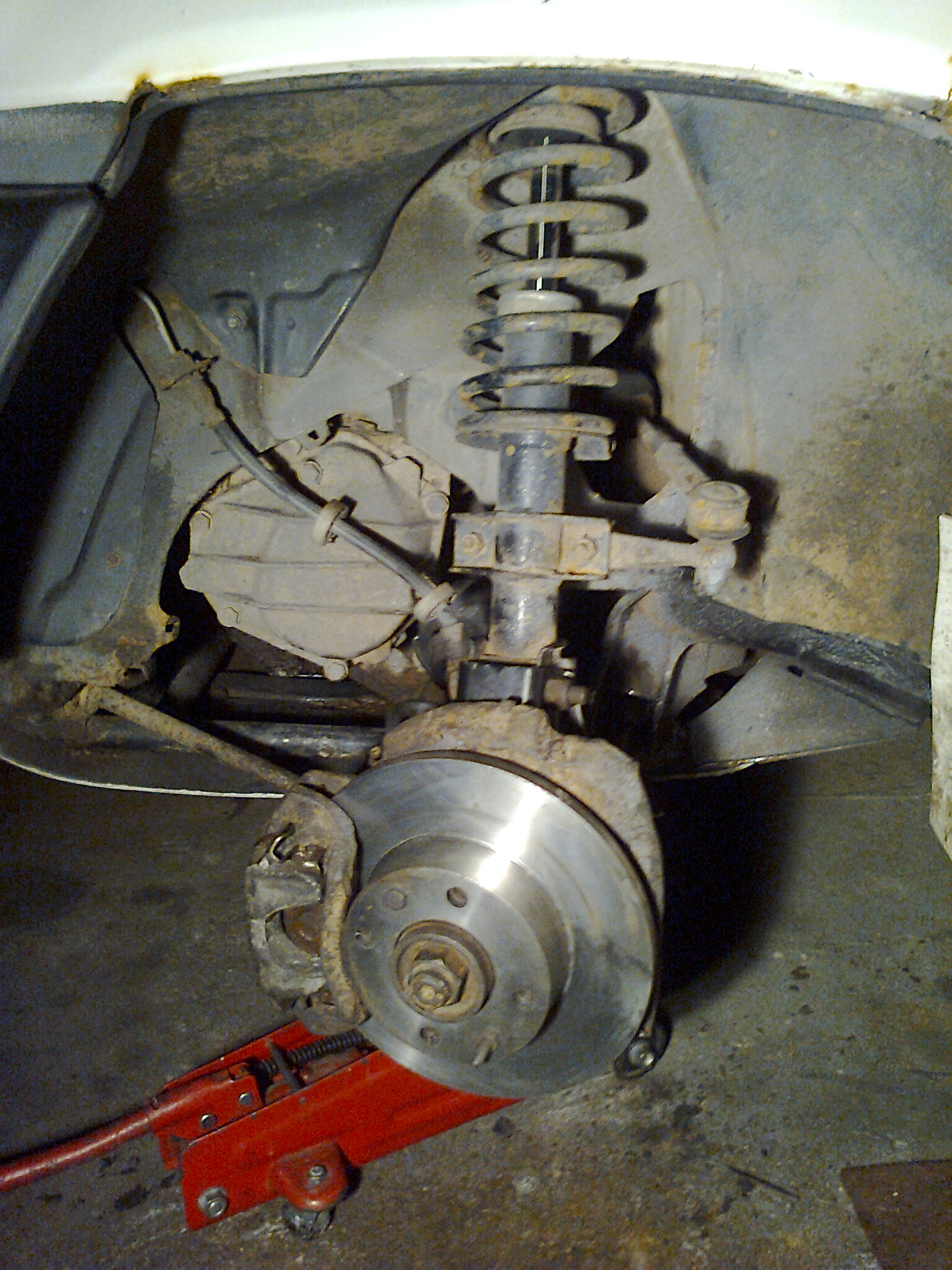

And attached to the car once more...hopefully strong enough to jack up on...too nervous to try...made it from thicker metal than Fiat did so should be fine really

I wasn't able to reconstruct the original sill drain holes but I did add some and included one for the jacking point box section as well...I think they rot in there because water just gets trapped in there...hopefully not a problem now!

Final bit today (before I ran out of gas

) was to put the arch patch on. Going to be tricky to protect against rust properly but will use all the tricks on the seam and plenty of underseal as well as lots of coats of zinc primer :slayer:

So that's the update anyway, maybe if I can get all back together in time (and the last bit of welding done) I can book an MOT :devil:...

And only then can it snow