Firstly, just to be clear, I'm not an engineer so there will be many people on this forum with much more knowledge than me who can correct what follows. Here's what I did..

Attempt 1 - No VVT Loosen or Phonic Relearn - Car sounded fine but P0009-62/P0011-61 faults (over advanced) after a few minutes

Attempt 2* - No VVT Loosen or Phonic Relearn - Car sounded fine but P0009-62/P0011-61 faults (over advanced) after a few minutes

* was really careful to make sure all the timing was spot on.

Attempt 3* - Loosened VVT AND Phonic Relearn - Car sounded fine, test drive, no error codes

* was really careful to make sure all the timing was spot on.

When fitting the belt with both timing tools locked there is no movement in the pulleys. If you fit the belt on the tight side anti-clockwise from the crankshaft as per instructions, in a taught position it naturally sits with a tooth from the belt squarely on top of a tooth from the VVT Sprocket (I guess people would describe this as half a tooth out). You then have to make a decision as to whether to pull it really really tight, or slacken it slightly. I tried both ways.

If you slacken it slightly, there is insufficient belt on the 'slack' side to get the belt around the tensioner, even when fully slackened off, I couldn't physically do it with the locking tools fitted. If you pull the belt really tight it is possible to fit it. I chose the 'pull in tight' option on both attempt 1 and attempt 2. After putting the car back together I got over-advance codes on both occasions. ( I also loosened the camshaft locking tool and fitted the belt one tooth over. i.e cam retarded 1/2 tooth, just to see what would happen and I couldn't refit the timing tool in this position)

The alternate option, and that specified in the service manual, is that you release the VVT sprocket. If you release the VVT sprocket so it is able to spin freely relative to the camshaft, it is easy to fit the belt and it finds a natural balanced position, you don't have to choose for yourself regarding the belt position or release the locking tools. You set the tensioner to it's maximum tension, you then lock the sprocket in that position with the front cam lock and all goes back together easily.

I marked my pulley up before starting this exercise and all appeared to be in exactly the same place before and after. It didn't appear to be any significant difference but may be the belt was actually a tooth different on the sprocket and the tensioning of the adjuster shifted the sprocket back to the roughly same point (even though this time it actually had more belt on the 'tight' side). I can't explain this I'm afraid.

Either way, when I put the car back together and idled it for 5 mins or so, I had no errors, both previous times I had over advance errors.

My advice based on this experience, is that if you are using timing tools in both the crankshaft and camshaft, then it makes sense to release the VVT pulley as per the Fiat instructions.

A few comments...

VVT Sprocket - I believe the VVT sprocket has around 30 deg of movement when the engine is running (see overview of VVT link below if interested or also fiat diagram attached.) Without the engine running the unit is locked from rotating by a lock pin internal to the VVT component (released by oil pressure ). I checked my VVT unit with the belt off and it had <1mm of play in it in the locked position. Not enough movement to explain any problems I was seeing.

)

VVT Sprocket Removal - The Fiat procedure says to do this with a "reaction wrench" on the camshaft splines. I did it with a 1/2 inch T55 drive and 30" breaker bar on the bolt head & a 24mm spanner on the camshaft to stop it turning. Two points here (i)

the fiat manual does not use the little black sprocket lock tool at this point. [

IMO If this is used then then the torque being applied to the bolt will be transferred to the internal lock in the VVT unit and I wasn't sure if that was appropriate] (ii) I made sure the sprocket lock tool from the rear of the camshaft was removed as I didn't want to damage the camshaft , but this has the disadvantage that it allows the Camshaft to move unless the 24 mm spanner is locked in position. Someone brighter than me can may be explain the safest/best method to remove this pulley.

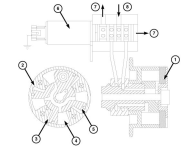

VVT Sprocket Installation Tool (small black tool) - This tool is an L profile. I believe most people fit it with the flat face on the cylinder head (there is a picture like this in the Sealey Timing Tool guide for example) - attached), however it appears to be designed with an L shaped profile because the L shape hugs the profile of the cyclinder head. This means the edge of the cylinder head is stopping rotation of the tool not the tightness of the retaining bolt. The bolt serves only to hold it securely. That said to fit the tool as it is designed and specified in the fiat instruction, requires the '

timing belt side protection' to be removed (see attached picture of side protection blocking tool). This only has two bolts but one is under the manifold heat shield, so that has to be removed as well. Personally, I decided not to bother at that point and went with the flat face orientation

.

IMPORTANT - the bolt that comes with my laser tool is the wrong thread for my cylinder head. I used one of the engine mounting bracket bolts to hold it in place (during installation) with a nut from one of the other brackets to effectively shorten the bolt length.

Belt Fitting 2 - With the sprocket bolt loosened, the belt fitting is easier. The tensioner is set at it

maximum tension prior to tightening the VVT sprocket bolt, then adjusted later. To ensure the sprocket doesn't move during tightening the VVT Sprocket Installation tool is fitted. I thought there was a bit of play in this tool (possible because I hadn't removed the rear timing cover), so marked the rear of the Sprocket against the cylinder head with a paint marker to check it was in the exact same place after torquing up. I also used a wrench on the camshaft (rightly or wrongly) because I didn't want to stress anything.

After tightening the pulley, I went through the usual process of rotating the engine & adjusting the tension a few times as per instructions.

MES "Cam Position" Parameter. After putting everything back together the Cam Position parameter was

0.00 deg at

idle. I have done two re-learns since then, one without

MES, once forced, and driven 50 miles and it is still at

0.00 deg at

idle, so I have come to the conclusion that this is the default setting at idle. ( I monitored cam position in

MES for the whole of the 50 miles and it stayed in line with the desired position pretty much the whole time). There are other parameters "

Learned VVT tooth position[1]" but I didn't check these so not sure if/when they changed during the relearn.

Phonic relearn. The official fiat documentation from 2007-14 says

"The cam/crank variation relearn procedure must be performed using the scan tool anytime there has been a repair/replacement made to a powertrain system, for example flywheel, valvetrain, camshaft and/or crankshaft sensors or components." I think this makes sense as a tiny shift ( the calculated position of the crank sensor relative to the cam sensor caused by e.g. a tighter belt, could presumably upset it. My understanding of a phonic relearn is that it can be done without

MES by revving the car to 6K 3 times once it has reached operating temperature (some people say 4K or 5K). I did this but I have no idea if it has any impact as my engine light wasn't flashing before I started. I was expecting the actual cam position to change from 0.00 deg at idle so was monitoring it but subsequently relalise it doesn't change. It

could be that the "

Learned VVT tooth position[1]" (1-6) parameters changed but I have no idea as I wasn't monitoring them til later. I subsequently ran a phonic relearn with

MES and it is much more visible as the engine light blinks, and then clears once it is run. (There is also a "Phonic Wheel learn status" but this seemed to change from "Not Leaned" > "In progress" > "Performed" each time I started the car, but I need to check that again as it seems wrong)

My final thoughts/opinion here are:

(1)

Releasing VVT Sprocket. If using timing tools in the crankshaft and camshaft, releasing the VVT Sprocket seems to be the most reliable method to ensure the

belt is fitted in the correct position. (This does release oil from the VVT sprocket cap so useful to have lots of rags under the sprocket at this point) but other than that is pretty straight forward..

(2)

Phonic Relearn. If using timing tools and releasing the VVT as above, then the timing has to end up accurate. The fiat service guide & lots of other comments on forums say to run a relearn afterwards. It takes a few minutes extra to do so and in theory can be run without

MES. I can't think of a reason not to (if the timing is in a known good state & the engine sounds fine prior to revving to 6K RPM).

It is clearly possible to do a timing change without the use of timing tools by marking the pulleys, there are lots of video's showing people doing this. It may be that using this method the pulleys settle into a more neutral position than they do when using timing tools and fitting the belt with the correct number of teeth on each side is easier as there is play in the system (removing the 1/2 a tooth out scenario). I can imagine marking the pulleys

and the old/new belts could result in reliable fitting, but if and when I do one of these again, I'll be (1) using timing tools and (2) releasing the VVT sprocket and (3) running a phonic relearn.