I think it originates from a 126 pre-1977 and the engine type-number would have an extra "5" in it if it was from an "R".

It might be supposed to have a few extra horse-power,; we'll see!

Apparently they were mean with the "R", or perhaps they were catering for the more discerning driver , but they didn't have synchro.

, but they didn't have synchro.

It actually cost £102 but there was no way I was driving to Hull so delivery was £50...still a bargain as you say.

I think it might already have been once transplanted into a 500 so it makes me wonder what went on?

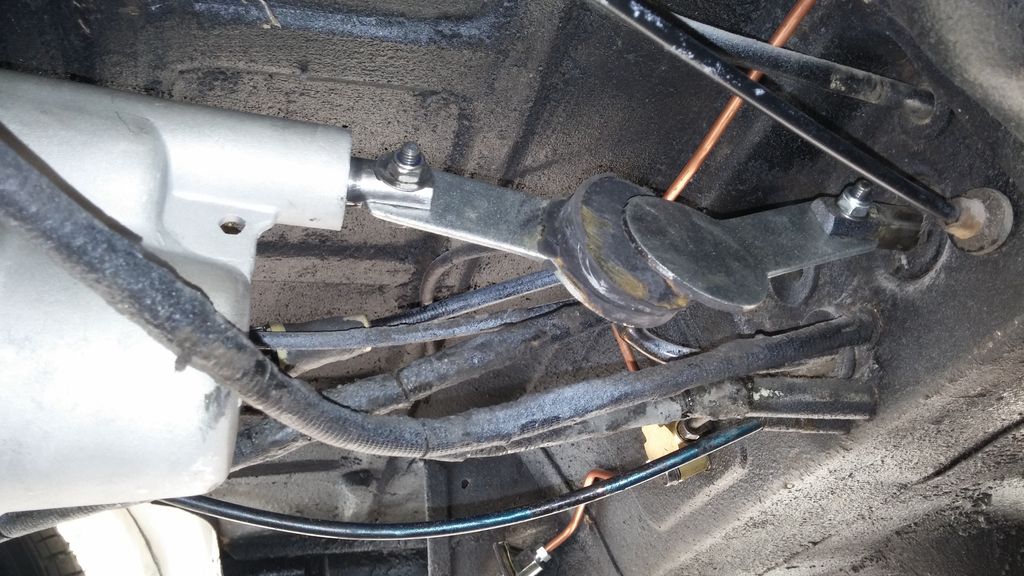

There don't seem to be 28IMB carbs without a return pipe, so someone must have blocked it (very professionally). The engine mounting has the long 500 studs. Somehow it is functioning with the 500-type thermostat housing (slightly modified). I'm not sure that the exhaust is 126 or 500.

There is atiny amount of end-play on the crankshaft but I am hoping that it's demise was because of a fault with the dynamo; the clue is that someone must have started to remove it as that securing strap takes a fair bit of deliberate effort to remove.

So now I have the full set of engines that I care to own (I don't want anything to do with those N and D engines) . maybe I can stop buying now.

. maybe I can stop buying now.

It might be supposed to have a few extra horse-power,; we'll see!

Apparently they were mean with the "R", or perhaps they were catering for the more discerning driver

It actually cost £102 but there was no way I was driving to Hull so delivery was £50...still a bargain as you say.

I think it might already have been once transplanted into a 500 so it makes me wonder what went on?

There don't seem to be 28IMB carbs without a return pipe, so someone must have blocked it (very professionally). The engine mounting has the long 500 studs. Somehow it is functioning with the 500-type thermostat housing (slightly modified). I'm not sure that the exhaust is 126 or 500.

There is atiny amount of end-play on the crankshaft but I am hoping that it's demise was because of a fault with the dynamo; the clue is that someone must have started to remove it as that securing strap takes a fair bit of deliberate effort to remove.

So now I have the full set of engines that I care to own (I don't want anything to do with those N and D engines)