AndrewRL

Member

I'm afraid I am after your expert opinions, advice etc again :worship:

I thought I ought to grease the king pins (new stub axles/king pins fitted about 2000km ago). I jacked up the car and managed to get my grease gun to work. I started with the offside and eventually got grease into the nipple (rather than just around it!). Now the Haynes book says to pump in grease until it appears around the king pins so I carried on until I could see a thin thread of grease coming out at the bottom of the stub axle just above the connection to the leaf spring.

I then did the same on the nearside but instead of a thin thread a large grease "plug" appeared out of the bottom of the stub axle. I went to wipe this away when I realised that there was a convex metal disk on the end of this grease plug . Looking at parts diagrams I assume this is supposed to sit at the bottom to hold in the grease (??). So I went back and checked the offside and gently poked my finger up from the bottom and found that there was nothing there and I could reach 2-3cm up

. Looking at parts diagrams I assume this is supposed to sit at the bottom to hold in the grease (??). So I went back and checked the offside and gently poked my finger up from the bottom and found that there was nothing there and I could reach 2-3cm up

My obvious questions are:

- when you grease these nipples where do you usually expect to see excess grease appearing?

- am I right that there should be this disk at the bottom of the stub axle?

- if the disk should be there - how critical is it (stops grease escaping? keeps dirt out?)?

- if the disk should be there - how is it attached? Is it something a novice can fix (or does it involve major work removing the hubs, stub axles etc)? the only reference I can find seems to imply that it is peened in (so hammered in I assume but that couldn't be done in situ)

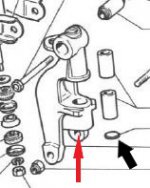

I may well have the wrong descriptions so attach a diagram - red arrow where I saw grease emerging and the "plug" appeared; black arrow showing what I assume is the disk.

Any help gratefully received

I thought I ought to grease the king pins (new stub axles/king pins fitted about 2000km ago). I jacked up the car and managed to get my grease gun to work. I started with the offside and eventually got grease into the nipple (rather than just around it!). Now the Haynes book says to pump in grease until it appears around the king pins so I carried on until I could see a thin thread of grease coming out at the bottom of the stub axle just above the connection to the leaf spring.

I then did the same on the nearside but instead of a thin thread a large grease "plug" appeared out of the bottom of the stub axle. I went to wipe this away when I realised that there was a convex metal disk on the end of this grease plug

My obvious questions are:

- when you grease these nipples where do you usually expect to see excess grease appearing?

- am I right that there should be this disk at the bottom of the stub axle?

- if the disk should be there - how critical is it (stops grease escaping? keeps dirt out?)?

- if the disk should be there - how is it attached? Is it something a novice can fix (or does it involve major work removing the hubs, stub axles etc)? the only reference I can find seems to imply that it is peened in (so hammered in I assume but that couldn't be done in situ)

I may well have the wrong descriptions so attach a diagram - red arrow where I saw grease emerging and the "plug" appeared; black arrow showing what I assume is the disk.

Any help gratefully received