stage 1 of the engine build:

After fitting the crankshaft and main bearings successfully, the crank turned round quite freely without any tight spots. So at least the welding of the crack didn't distort anything.

I then fitted the 2 barrels, but soon found out you cant do that on the 500 engine. Because the big ends are larger than the bore size you have to fit the pistons in the barrels first and then fit them to the block. I'm sure I didn't have this issue of the 650 engine.

The pistons were a little difficult as the bottom of the barrels are rather thin after the rebore for the 540 pistons. But I got them in eventually.

The barrels were held in place with my Fiat workshop specialist tools (a tube and a nut).

Big ends fitted and torqued up. And a quick check to make sure the crank still turns - with a good dose of oil down the bores.

There's not a great deal of room between the bottom of the barrels and the crankshaft weight. I don't know how you boy racers get away with fitting 650 barrels?

The new timing gear was fun. I had to use the old one to determine the position of the cam before fitting the chain and cam sprocket. Its daft really, the cam has 5 holes and the sprocket only has 4.

Just in case you don't have the old one at hand with any witness marks. You need to have the pistons at top dead centre then the camshaft should be sitting with the 2 lobes for N01 sitting either side of the cam follower holes. ie: if you had the rocker gear in place then No1 inlet and outlet would be rocking.

The chain sure is tight, it took quite a bit of force to get the sprocket on the end of the cam shaft.

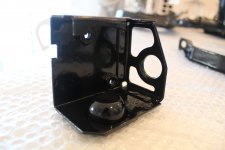

When I came to fit the oil pump and cover I came across a slight issue.

I had a choice of 2 cams - they both seemed the same to me so I fitted the cleanest one with least wear to the lobes etc.

Now something I had never noticed until now was there are 2 types of drive for the oil pump - one is 6mm across flats, the other is 7.5.

Turns out I have fitted the D one as the N,D & early F's had the 6mm one.

Lucky really because out of the oil pumps I had the 6mm one was the best one with virtually no play. I guess going by the engine when I took it apart that it had not long been rebuilt before the problem with the pickup pipe and must have had a new pump fitted then. I couldn't see any wear or damage to it so couldn't see the point of a new one.

So with the cam all lined up and tabs bent over the nuts it was time to fit the cover with a new seal. I fitted the pulley in place before tightening the bolts up to make sure the seal was sitting snuggly. This has now been given a coat of paint so will be fitted soon.

All the newly plated bolts all make it look nice and new.

Next stage, fit the pulley and then the head.