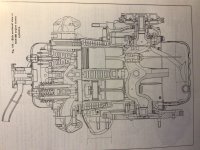

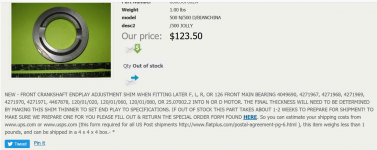

Following up Ian's comments. The only way to check the end-float of the crankshaft is to bolt the whole unit up with the big nut---washers, sprocket, pulley, oil-spinner, tab washer and then the big hollow nut. You don't need to torque the nut up to the full amount, just fairly tight. When you have done that you will find that you can push the crank TOWARDS the flywheel end--just. I normally build them up with just 10thou end float, so that you are able to slide a 10thou feeler between the rear (t/c end) of the crankshaft and the end surface of the bearing. The bearing with the 2 chain-channels goes to the timing-chain (t/c) end. As Ian mentioned, the factory clearance of between 12 17.3 thou is quite big!