Lord Peter Toone

New member

- Joined

- Apr 20, 2021

- Messages

- 5

- Points

- 1

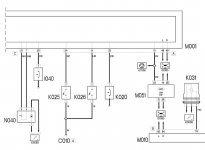

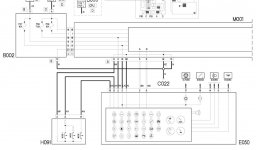

Hi all, quite new to these Forums, as i`ve always thought that people in here were aliens, and how wrong thinking that. You see threads and wonder if they really work, Well, here`s a braintester for those into electrics and where they are. I`m quite machanically minded with most vehicals, having repaired many myself, but this is going to be a game changer for me, and i`m investigating this one, as i like to see it right, like everyone. I have a 2008 Rapido motorhome, and i`ve worked and saved to get this, like we do before we retire, anyway, it has a slight problem, and i`m sure someone could help. The fuel gauge has stopped working. When i turn on ther ignition, the yellow low warning light comes on, and it goes out with the rest, so i know there is power getting to it, as i know it worked the last time i drove it, as i put fuel in it, as it told me to. It just passed it`s Mot, so while standing for a few months, i`m trying to locate the A653 unit under the dash, but where is it? Black 6 wires, held in place with 1 bolt, as i have traced it to be the culprit. I`ve pulled out the block stop with the 2 positive wires to reset, but with no pleasing me. Inside is a pcb that common fault is dry soldering, and i`m in the mood to get it fixed. Any help will be great, and i`m here to help others.